- Joined

- Aug 23, 2014

- Messages

- 216

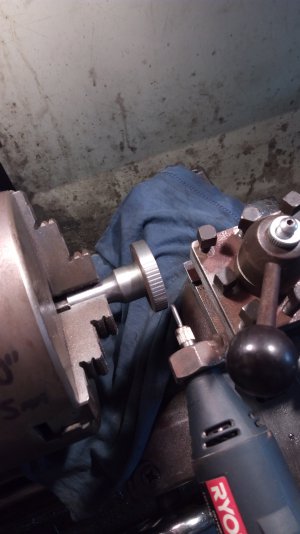

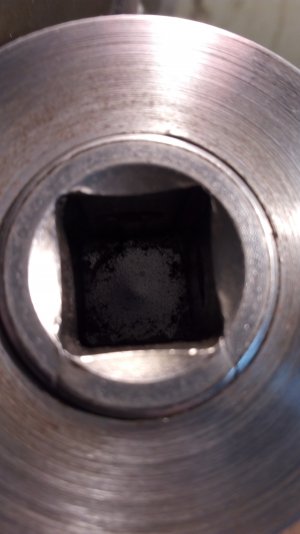

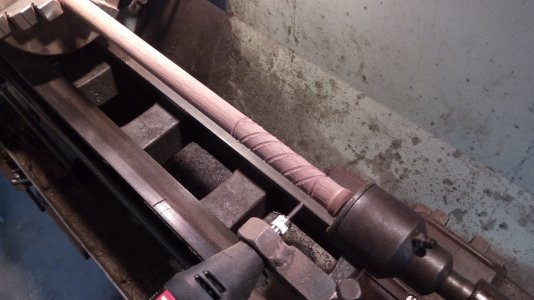

It swings... Some kind of keeper through the spindle, that will be the base sorted.

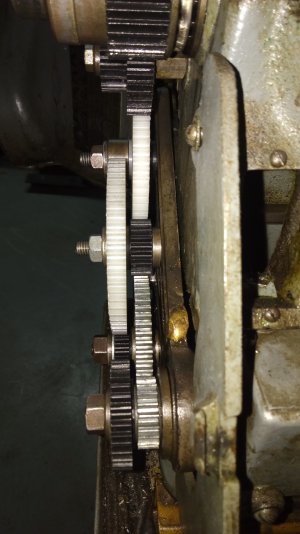

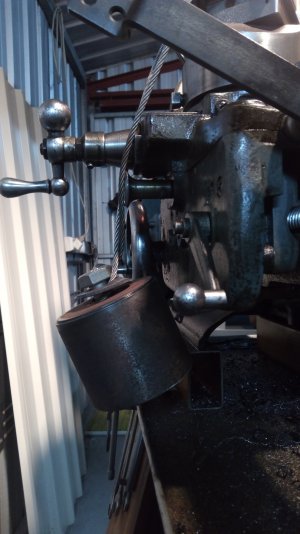

As good as it can be, not today as a lot of measurin' an' checkin' an' refinin' the setup gotta happen first.

Will post another of this when it gets done.

As good as it can be, not today as a lot of measurin' an' checkin' an' refinin' the setup gotta happen first.

Will post another of this when it gets done.