- Joined

- Aug 23, 2014

- Messages

- 214

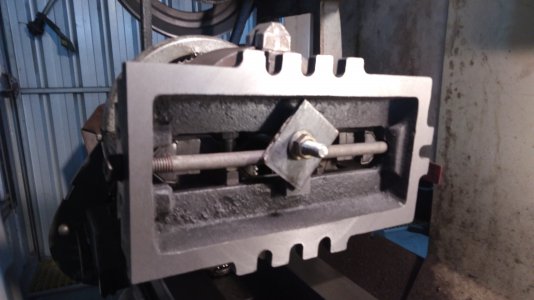

1/2" centres on the outer legs, 3/4" centres on the inner gives me 1/4" increments.

Smallest setting is about 500mm x 280mm, largest 1800mm x 600, yet to be confirmed. Still need to work on width capacity... Another day...

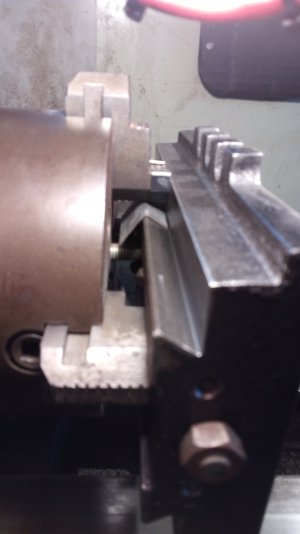

First "production" run for the $50 bunning's clearance item drill press. Motor got fairly warm drilling 180 holes.

Smallest setting is about 500mm x 280mm, largest 1800mm x 600, yet to be confirmed. Still need to work on width capacity... Another day...

First "production" run for the $50 bunning's clearance item drill press. Motor got fairly warm drilling 180 holes.