- Joined

- Jun 6, 2014

- Messages

- 183

Hi All!

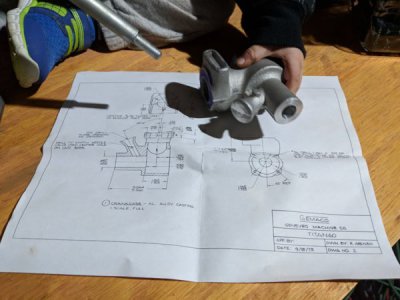

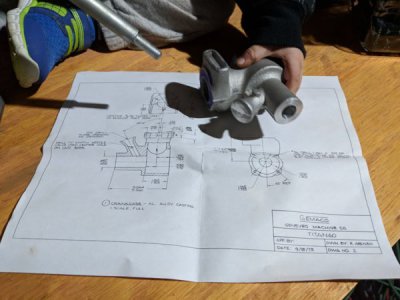

I bought a set of plans and a kit containing the raw materials and a few castings to build a small "cox" style engine like those used on model airplanes back before brushless took over the market. I briefly began to machine it, but with no real planning and sort of "shooting from the hip" about two years ago. Fortunately, I didn't ruin any of the castings, although I got dykem on a bunch of surfaces that will remain as cast and which I did not want to sand or pain as I like the look of them. Anyway.... one night the wife said "I think I'm pregnant" and that was the end of that.

Last night I finally drug the box of small paperweights out and started messing with it again. This time with a toddler sitting on my workbench trying to touch everything I looked at. That's something I never planned for, but sometimes we don't make the best plans I guess..... (that's a bit deep of a statement but is mainly there to account for the many pictures which contain the odd shoe, small hand, or drool).

I got so far as boring out the journal for the main bearing (a yet to be machined bronze bushing), facing off the back of the engine where the mounting plate will attach, and beginning to bore out the crankshaft cavity. By the time I started that third step my left arm felt like it was going to fall off. My son had grown bored of playing with my drill and turning the feed handles on the mill, and had decided that the only way progress would continue is if I held him so he could watch while I worked.

I bought a set of plans and a kit containing the raw materials and a few castings to build a small "cox" style engine like those used on model airplanes back before brushless took over the market. I briefly began to machine it, but with no real planning and sort of "shooting from the hip" about two years ago. Fortunately, I didn't ruin any of the castings, although I got dykem on a bunch of surfaces that will remain as cast and which I did not want to sand or pain as I like the look of them. Anyway.... one night the wife said "I think I'm pregnant" and that was the end of that.

Last night I finally drug the box of small paperweights out and started messing with it again. This time with a toddler sitting on my workbench trying to touch everything I looked at. That's something I never planned for, but sometimes we don't make the best plans I guess..... (that's a bit deep of a statement but is mainly there to account for the many pictures which contain the odd shoe, small hand, or drool).

I got so far as boring out the journal for the main bearing (a yet to be machined bronze bushing), facing off the back of the engine where the mounting plate will attach, and beginning to bore out the crankshaft cavity. By the time I started that third step my left arm felt like it was going to fall off. My son had grown bored of playing with my drill and turning the feed handles on the mill, and had decided that the only way progress would continue is if I held him so he could watch while I worked.