-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Joined

- Mar 17, 2017

- Messages

- 87

Variations on a theme - got a 10-inch spring-loaded rod I load between the tailstock and the indentation in the piece and indicate off of that. Spring loading keeps it from falling out, and makes it a doddle to align precisely. Horses for courses - or there's more than one way to skin a feline.

- Joined

- Dec 2, 2012

- Messages

- 1,721

My 4 jaw is calibrated

Thats interesting, do you use a dial indicator on the jaws to locate an off center part ?

Stuart

- Joined

- Nov 17, 2017

- Messages

- 1,525

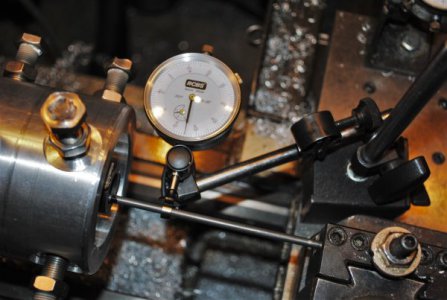

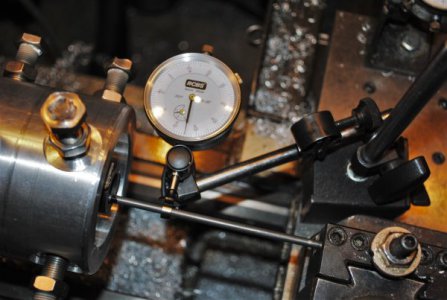

I use a tap follower and dial indicator to center things in the 4-jaw with a punch mark.

Setup the part in the 4-jaw, then bring in the tailstock with the center and press the tap follower into the mark.

Setup the dial indicator to read runout. Be sure to preload the tap follower at least 1/2 way in.

Then it's just a matter of dialing it in to zero on the indicator.

Setup the part in the 4-jaw, then bring in the tailstock with the center and press the tap follower into the mark.

Setup the dial indicator to read runout. Be sure to preload the tap follower at least 1/2 way in.

Then it's just a matter of dialing it in to zero on the indicator.

- Joined

- Apr 8, 2013

- Messages

- 1,976

That wobbler is really cool. I had no idea they existed. This is the tool I use. It's a piece of 3/16" music wire mounted in a toolholder. I have a collar in the middle that I use to indicate runout run out. On the far end I a 60 degree point for punchmarks or use another collar if I need it to read the inside of a bore. Because the DI is on the xslide I can use the long feed handwheel to sweep back and forth to insure perfect alignment of the part from end to end. In the pic I'm dialing in the chamber in a 3 inch stub barrel for a 12 ga to .458 SML conversion. Of course this setup doesn't amplify the runout like the wobbler tool does but it works pretty well.

- Joined

- Dec 9, 2016

- Messages

- 1,133

His 4-jaw chuck is probably calibrated using one of those newfangled Spurving Bearings which makes the need to locate anything unnecessary! Of course it could also just be the common Nut that controls the 2-Jaw Volcalizer chuck is the real problem by producing needless chatter!Thats interesting, do you use a dial indicator on the jaws to locate an off center part ?

Stuart

- Joined

- Dec 2, 2012

- Messages

- 1,721

one of those newfangled Spurving Bearings

I've had one of them on back order for a while now but they are still marked as out of stock.