-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tool Height Tolerance

- Thread starter epanzella

- Start date

- Joined

- Oct 3, 2015

- Messages

- 982

I've done barrels up to 30", but that requires me to remove my thread dial to get that much travel. I use Ashburn 9000 water soluble coolant.

I didn't mention it before, but this is on a 13" South Bend. It's a good stiff machine and that's probably why I don't have many problems with chatter. I can't get away with this on my heavy 10".

I didn't mention it before, but this is on a 13" South Bend. It's a good stiff machine and that's probably why I don't have many problems with chatter. I can't get away with this on my heavy 10".

- Joined

- Sep 29, 2014

- Messages

- 2,102

U

umahunter

Forum Guest

Register Today

- Joined

- Jul 2, 2014

- Messages

- 7,594

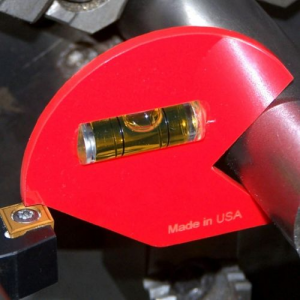

What do you do if the work is partially finished in the chuck and you want to change to a different tool holder and/or put a different height tool in it?I have one of these from edge technology it has an adjustable bubble you set to your machine then put it in the chuck and level your tool View attachment 257321

U

umahunter

Forum Guest

Register Today

I have holders for each tool I have so I don't run into that problem but I believe they make a similar level you don't mount in your chuck you just hold against the stock but since I bought holders for each tool bit i have I bought this one

- Joined

- Feb 1, 2015

- Messages

- 9,602

I have holders for each tool I have so I don't run into that problem but I believe they make a similar level you don't mount in your chuck you just hold against the stock but since I bought holders for each tool bit i have I bought this one

Like this.

https://www.ebay.com/itm/Lathe-Gage...hash=item5649056a5f:m:m3NZb7KTSDbcKWZzGIrJgqA