- Joined

- Nov 24, 2014

- Messages

- 3,151

In addition to what francist wrote, there is very little chance (essentially zero chance) that four different tools in a 4WTP will have the same cutting height.

That's why you need to shim each cutter individually.

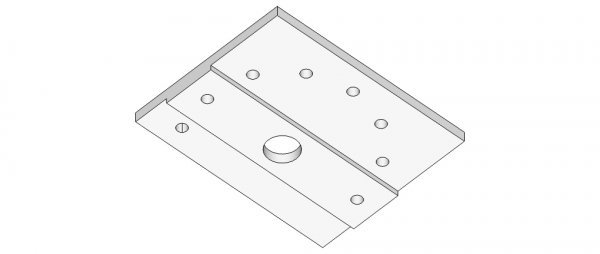

The comments that my earlier reply has motivated makes it clear that I made too many assumptions and also didn't specify a detailed description of what type of 4WTP we were discussing. Francisist referred to "An ordinary 4-way bolts straight to the compound without a central pillar (snip)". That's the kind I was talking about.

The ideas of using only indexable insert tooling and/or only new (not resharpened) brazed carbide bits and/or a custom design 4 Way didn't occur to me. I guess they should have. My reply was based on the use of various sizes and grinds of HSS bits which, in my experience, are very common.

Whether you call shims spacers or spacers shims, isn't the function the same?

Last edited: