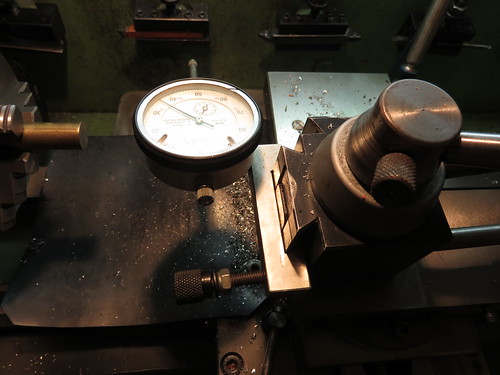

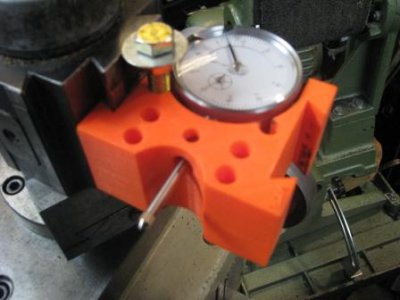

I know this thread is a little old but I figured I'd share version. A few months ago I decide to make an indicator mount for each of the lathe workstations at the school. Very similar to the other designs in concept but using minimal materials. These are BXA sized. I attached them using a short length of aluminum hex turned down for the mount and held in place with a hex screw. Each end of the mount is tapped so the indicator can be moved for face indicating. I found teaching 4 jaw indicating a treat with this mount. This photo was taken during the construction of the BXA racks. These racks have worked great also.