- Joined

- May 24, 2012

- Messages

- 395

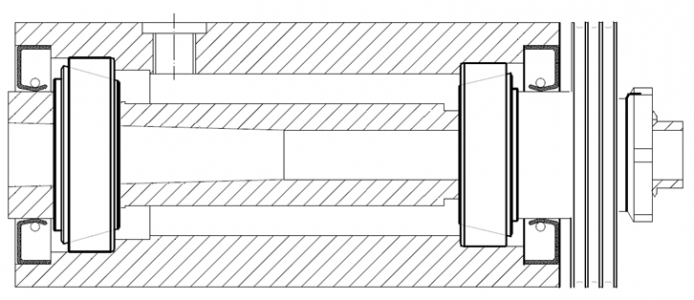

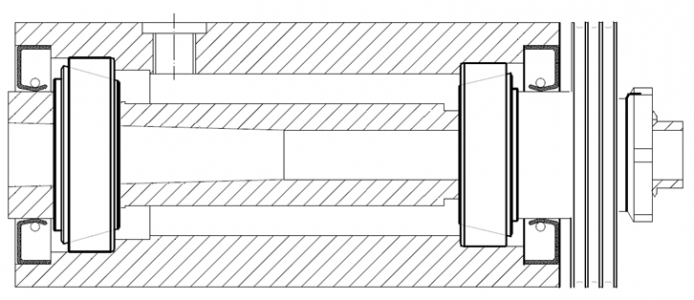

Since I had created this drawing, cannot wait to see it done.

The quality wasn't good but the layers movie looks cool: https://flic.kr/p/zMin27

Carcass with oil plug and bearing races pressed

Axle, initial cuts

My setup for finishing the axle. It was turned between MT 02 arbor and center

The quality wasn't good but the layers movie looks cool: https://flic.kr/p/zMin27

Carcass with oil plug and bearing races pressed

Axle, initial cuts

My setup for finishing the axle. It was turned between MT 02 arbor and center