Ok- so to recap, the CVD vs PVD would be for moderate temperature chemical vapor deposition vs physical vapor deposition, the former being apparently good for high toughness and surface roughness resistance, and the later being particularly good at high temperature resistance and high speed machining impact resistance. This make sense then than Tormach would have chosen the PVD vs CVD. Perhaps the CVD might be the better option for the home gamer with an older (slower spindle) machine. That means we probably want an insert grade starting with NC.

From there, unless you want a dedicated tool per material type, it seems to me that a universal tool for steel, stainless, and cast is more economical. Therefore we'll want a "5" after the NC. Note that Korloy also has an NCM (as opposed to NC5) type tool. Other than a textual description for the use case (interrupted cuts, etc) it doesn't seem to define the M in the "Indication of Work" column on their grade code. Never the less, NC5

xxx or NCM

xxx is probably on our radar.

From there, the machining type column. Now I'm sure there is documentation somewhere about this, but as best as I can gather- turning means the work is spinning and milling means the tool is spinning. Perhaps that affects the tool geometry, but I can't find data on this. Since Tormach chose a milling type tool, I can only guess we want a milling type as well. So now we have NC53

xx or NCM3

xx.

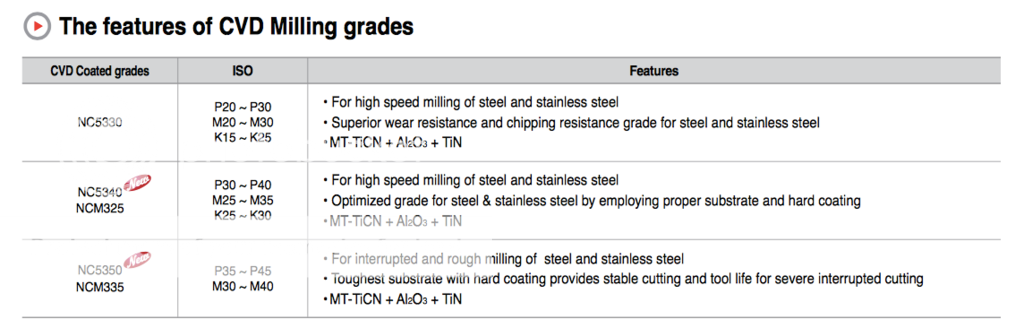

I guess the ISO grade column would depend on the application. The Korloy catalog defines the three insert options up to this point:

I'm guessing that any NC53

xx or NCM3

xx would be an excellent choice for most machining tasks in the hobby shop, though perhaps the NC5350 or NCM335 might be the best option since a flycutter would naturally see an interrupted cut pretty much constantly. On top of that, the categorization states that higher designation numbers are for slower speeds and heavier feeds.

(And score. There's plenty of NCM335 inserts on ebay.)