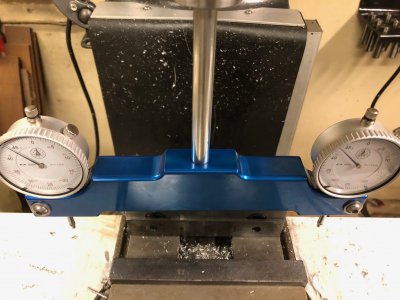

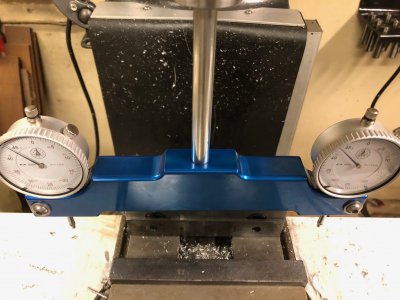

Good afternoon guys,well taking the advise of the membership here I decided to go ahead and anodize my tramming gage. Na I have never done this before but I did have the ideal few yrs ago and never follow through mainly because I never made anything out of aluminum.Well yesterday was a test run which went very well.But today was kinda opposite.As you can see there are few flaws and there is also one on bottom side.What I did different today which I had forgot was to use my Purple Power to clean the part before it went into the degreaser. I thought that maybe the degreaser would have been good enough but I guess I was wrong. I know I could strip it down and do it again but na I am going to leave my flaws to serve as a reminder for me not to take short cuts when it comes to cleaning.So next going to check the head again and fine tune it.