- Joined

- Dec 11, 2013

- Messages

- 302

I know I said I was going to re-check the Tram and post some pic's of the setup (2) weeks ago but the CEO (Cheif Enterainment Officer) - IE: Wife had a few other plans.

I got back down in the shop yesterday and here are the results:

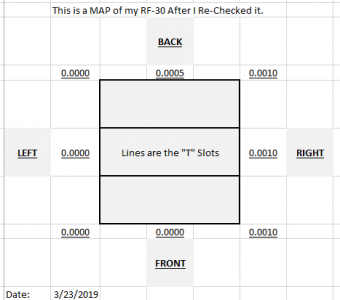

The TRAM is still excellent, altjhough it does seem the aluminium shims did compress slightly, about .0005.

Here are (2) angles of the Setup for the indicator (Note: before I zeroed it).

And the greatest Minus and Greatest Plus varations.

Overall I'm Happy.

I got back down in the shop yesterday and here are the results:

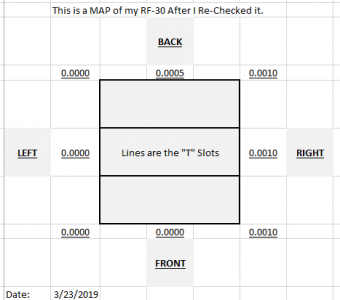

The TRAM is still excellent, altjhough it does seem the aluminium shims did compress slightly, about .0005.

Here are (2) angles of the Setup for the indicator (Note: before I zeroed it).

And the greatest Minus and Greatest Plus varations.

Overall I'm Happy.