- Joined

- Feb 27, 2015

- Messages

- 105

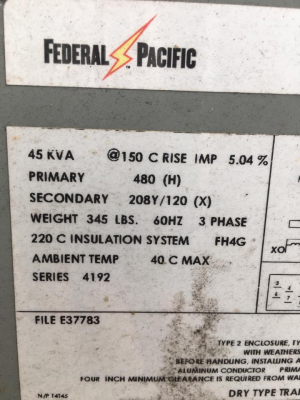

I have a mill that is wired for 440v, 3 phase at the power box. I have 220v, 1 phase. If I had this Transformer and a VFD to convert up to 3 phase, would I be able to wire it up to the mills power box and it would produce the voltage necessary? I wouldn't have to replace the 2 speed motor on the mill, convert a new motor, etc...

Please educate me!

Please educate me!