-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Treadmill motor conversion for planer feed - running too fast

- Thread starter KevinH

- Start date

Really? I didn't even think that it could have been threaded in place. I'll give it a tryOn the treadmill motors I've encountered, the pulley is LEFT-HAND threaded onto the motor shaft. Of course, yours may be different ... but it might be worth a try.

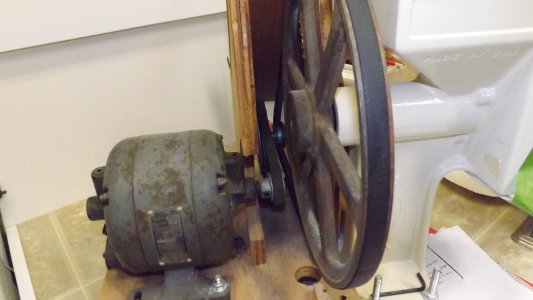

Very clever system. I've found a source for pulleys, shafts, etc in the UK but by the time I've added up all the parts it's not coming out much less than a new 3 phase motor and a VFD. But maybe I'm over-engineering it! I have some more thinking to do.Here's another simple and very cheap jack shaft I made for my wife's grain mill. Uses cheap flanged bearings and plywood for case and belt guard.

View attachment 319607View attachment 319608

OK - next stupid question: How do you remove a pulley that's threaded on? Do you have some way to lock the spindle?On the treadmill motors I've encountered, the pulley is LEFT-HAND threaded onto the motor shaft. Of course, yours may be different ... but it might be worth a try.

- Joined

- Aug 3, 2017

- Messages

- 2,437

Impact gun and pliers on the shaft.OK - next stupid question: How do you remove a pulley that's threaded on? Do you have some way to lock the spindle?

Though, looking at that picture, it looks like it is keyed on the shaft? Can you take a better picture of the end of the shaft?

- Joined

- Aug 3, 2017

- Messages

- 2,437

Ah, guess I was imagining dirt as a keyway on the old shaft picThe motor shaft is covered entirely by the pulley. Theres no obvious keyway but on closer inspection I do see the beginnings of threads on the motor shaft

Ah, guess I was imagining dirt as a keyway on the old shaft pic

DIRT?? On MY pulley?! How dare you Sir! I'll have you know I run a tight ship at Harrington Harps

OK so, I've spent most of the day wondering in what sort of arrangment you can possibly use a pliers and an impact gun to remove a pulley like this

Is an impact gun the same thing as an impact driver?

- Joined

- Aug 3, 2017

- Messages

- 2,437

An impact driver (the drill-like thing) is a really low powered version of an impact gun, but it might work too. The trick here is going to be to find some part of the shaft you can hold on to and let the impact driver/gun turn the pulley, otherwise it'll just spin. I'm not sure I see any part of it that'll work there (assuming the big black disc spins as well!).DIRT?? On MY pulley?! How dare you Sir! I'll have you know I run a tight ship at Harrington Harps

OK so, I've spent most of the day wondering in what sort of arrangment you can possibly use a pliers and an impact gun to remove a pulley like this

Is an impact gun the same thing as an impact driver?

Is that indent in the shaft threaded? If so, you might be able to hold the shaft from the front with a bolt? At that point, you could clamp some vice grips on the big rotating masss, and smack them with a hammer(something heavy to give it a good impact