-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

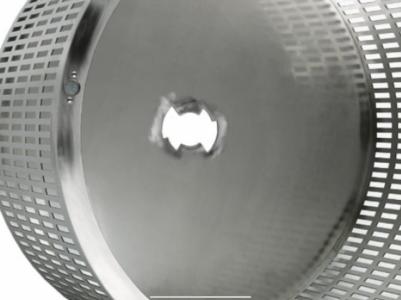

Treadmill motor shaft.

- Thread starter J81

- Start date

You can certainly make that motor work for the tumbler, but a rigid coupling like @RJSakowski suggested seems like the better way to go. In that case you would mount the motor frame to the outer drum and attach the inner drum to the motor shaft via a solid coupling. You still need a bearing mechanism for the inner drum, but given the slow speed of the rotation you might get away with Delrin or UHMW strips to support it.

My simple, caveman brain was thinking of supporting the drum with small wheels, at the end of threaded bar, running the length of the drum.

I did keep the bearings when I stripped the treadmill.

I still have the control board and choke if they are any use to anyone?

I did keep the bearings when I stripped the treadmill.

I still have the control board and choke if they are any use to anyone?

I think that would work: I would suggest cobbling a rough model with plastic buckets and your bearing idea to test the concept.

And I would keep the motor controller because that might be just what you need to reduce the motor speed to fit your application.

And I would keep the motor controller because that might be just what you need to reduce the motor speed to fit your application.

The speed controller I bought off Amazon seems to be working really well.

The one in the treadmill wasn’t like any of the YouTube videos I watched.

The treadmill was brand new but not working. Power was going to the board but I think the lcd control panel was broken.

It was cheap, Chinese, infomercial tat.

The one in the treadmill wasn’t like any of the YouTube videos I watched.

The treadmill was brand new but not working. Power was going to the board but I think the lcd control panel was broken.

It was cheap, Chinese, infomercial tat.

- Joined

- Sep 5, 2013

- Messages

- 3,207

Just eavesdropping a little here. If you did go with the “caveman concept” above, a friction drive off the motor to the outside of the drum might also work and may eliminate the need for the gear reduction assembly. Simply, the motor shaft gets equipped with a rubber or similar roller and is held against the circumference of the drum by (usually) some spring tension. With a small drive wheel against the larger drum circumference the reduction can be fairly dramatic. Just something to think about.My simple, caveman brain was thinking of supporting the drum with small wheels,

-frank