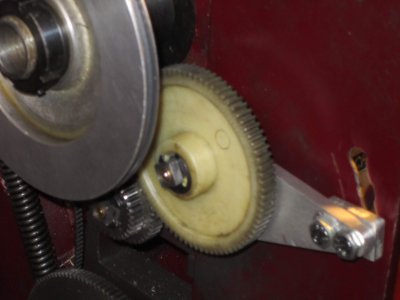

I have 2 9x20 lathes. I bought the Harbor Freight about 6 yrs ago on sale because it was a bargain. A short time later I traded an extra Drill Mill for a Grizzly with the factory stand. I cleaned and "set up" the 2 lathes and have used them regularly. I have larger lathes and never felt the need for the tumbler reverse for threading. However I found that I was constantly disengaging the gear train to make short cuts and for polishing.

This summer I decided to make the tumbler for my lathes and for a machinest friend who is struggling with cancer.

After studying various posts on the net I decided to follow the plans posted on the Yahoo 9x group with several mods

.

I made the knob with a 60 degree taper that screws into an enlarged hole in the slot to lock the tumbler into reversed, forward and neutral positions.

A brass ring is attached to the knob to facilitate knurling. My cheap knurls didn't want to handle the hardened stainless steel.

The bushings have oversized holes to permit precise alighnment of the gears.

I made 4 of these tumbler units. I have an extra if anyone is interested.

Joe

My next project is installing my Sinpro dro on my Enco mill.

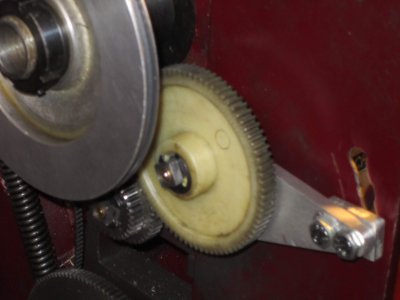

This summer I decided to make the tumbler for my lathes and for a machinest friend who is struggling with cancer.

After studying various posts on the net I decided to follow the plans posted on the Yahoo 9x group with several mods

.

I made the knob with a 60 degree taper that screws into an enlarged hole in the slot to lock the tumbler into reversed, forward and neutral positions.

A brass ring is attached to the knob to facilitate knurling. My cheap knurls didn't want to handle the hardened stainless steel.

The bushings have oversized holes to permit precise alighnment of the gears.

I made 4 of these tumbler units. I have an extra if anyone is interested.

Joe

My next project is installing my Sinpro dro on my Enco mill.