- Joined

- Nov 14, 2016

- Messages

- 2,997

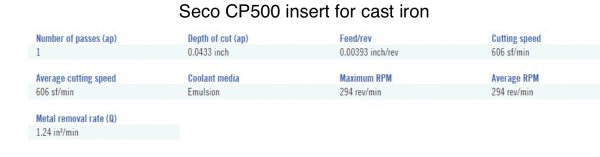

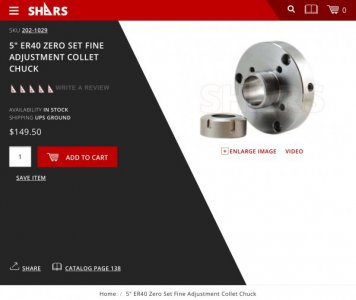

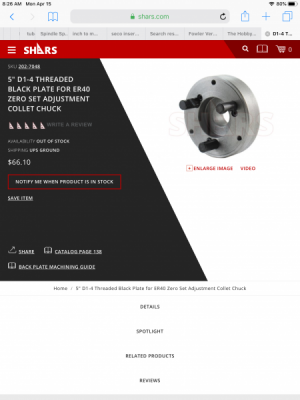

I need to turn a couple of cast iron lathe chuck backplates. All I have at the moment is a set of 1/2" carbide insert bits. I do have some 3/8" HSS blanks I can grind.

I've actually never used carbide tools, other than boring bars. Also my first time turning cast iron. I gave a test cut on the cast iron and am not impressed with the finish, but there are a million variables other than the carbide that could be to blame.

If HSS is generally preferred anyway, then it is worth putting this aside for a day and grinding some tools. If carbide works better, then I'll spend a little more time getting things adjusted right.

Plates are for 6" chucks on a 10x24 lathe. This is the first real project with this lathe since getting it set up.

I can see why people don't seem fond of working with cast iron, it is like standing in front of a sand blaster.

I've actually never used carbide tools, other than boring bars. Also my first time turning cast iron. I gave a test cut on the cast iron and am not impressed with the finish, but there are a million variables other than the carbide that could be to blame.

If HSS is generally preferred anyway, then it is worth putting this aside for a day and grinding some tools. If carbide works better, then I'll spend a little more time getting things adjusted right.

Plates are for 6" chucks on a 10x24 lathe. This is the first real project with this lathe since getting it set up.

I can see why people don't seem fond of working with cast iron, it is like standing in front of a sand blaster.