So its been a while! Ive been really slacking this past month! Yesterday i picked up my Kennedy roller for the final piece of the puzzle for my shop (for now). I spent prob 4 hours organizing my tools and cutters to get set up. What i may do if anyone is curious is take a youtube vid to show how i am set up at this point drawer wise.

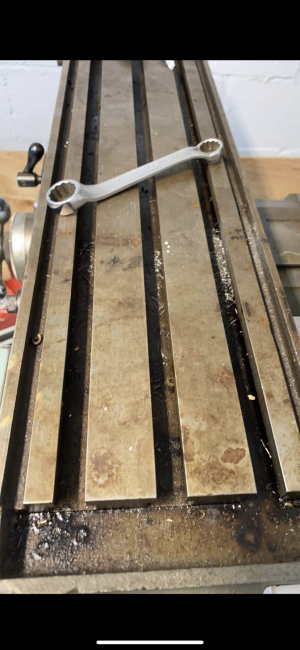

Tonight i started on cleaning the South Bend. I took the tailstock off and apart to clean up and there was quite a bit of chips inside the barrel so i took it completely apart and cleaned it all out lubricated everything and back together. Next was to clean the apron. To do that i decided i wanted to take all of the slides off to wipe it down and start fresh. Not alot of chips but some old grease needs to be cleaned up tmr when i start again. I am however not pleased with how the owner i got it from painted the lathe. He painted over the gib screws and got a little messy and got a little on the ways. I believe this was a rush paint job when he got sick and was getting ready to sell his stuff. Still was a great machinist but some stuff i am a little surprised about. Tmr i will finish cleaning everything up and put the slides back together. Over the winter i may take it all apart and do a good cleaning of the apron. And other parts like replacing felts.

I do want to ask if anyone knows if i could take the saddle off of the lathe without removing the apron? I would like to clean the ways on the saddle but i dont want to take the apron off at this time.

Cost: 890$

Hours of Labor: 62.5

Tonight i started on cleaning the South Bend. I took the tailstock off and apart to clean up and there was quite a bit of chips inside the barrel so i took it completely apart and cleaned it all out lubricated everything and back together. Next was to clean the apron. To do that i decided i wanted to take all of the slides off to wipe it down and start fresh. Not alot of chips but some old grease needs to be cleaned up tmr when i start again. I am however not pleased with how the owner i got it from painted the lathe. He painted over the gib screws and got a little messy and got a little on the ways. I believe this was a rush paint job when he got sick and was getting ready to sell his stuff. Still was a great machinist but some stuff i am a little surprised about. Tmr i will finish cleaning everything up and put the slides back together. Over the winter i may take it all apart and do a good cleaning of the apron. And other parts like replacing felts.

I do want to ask if anyone knows if i could take the saddle off of the lathe without removing the apron? I would like to clean the ways on the saddle but i dont want to take the apron off at this time.

Cost: 890$

Hours of Labor: 62.5