Take a piece of round & drill it under the size of the pipe cut a to the center then chuck it back up clamping until the slit closes then bore it to the amount of press you need to hooks the piece being turned. I'd mark it where it is in the chuck so you put it back in the same place every time. The slit should be between jaws. Using a 4 jaw would allow you to fine tune as much as you need.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

[How do I?] Turning Thin Wall "tube."

- Thread starter BellyUpFish

- Start date

- Joined

- Dec 3, 2013

- Messages

- 1,844

Oh, for that I'd bore some soft jaws. These are pretty basic, and can be made to support nearly 100% of the OD, thus preventing virtually all egging. You just have to bore them the right size.

http://www.hobby-machinist.com/threads/procedure-for-boring-soft-jaws.37215/

http://www.hobby-machinist.com/threads/easy-soft-jaws.17043/#post-142284

:+1:

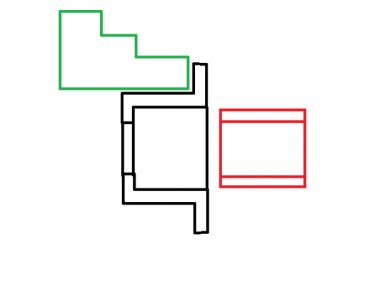

I have also made what I call "Top Hat" collars to hold the parts. Sorry for the crude drawing but it was all I could do at work.

The ID of the "Hat" is cut a few thou larger than the OD of your part. Depth is less than the length of the part. The brim of the "Hat" allows you to index the collar on the face of the chuck jaw.

Once the "Hat" is turned, cut a slot through one side so it will compress on the part.

- Joined

- Sep 29, 2014

- Messages

- 2,102

Inexpensive work holding, if you groove or even turn the end there is no loss as they are still usable, much like soft jaws they are made to be cut then replaced when needed. As seen a 2 1/2" Dia. arbor is only $44.00, if it makes only 50 parts it is still a bargain.Those work great, but for facing to length, you will end up cutting grooves in them. Those are more for turning OD's. They will keep things round and concentric. Used many, made quite a few.

- Joined

- Sep 18, 2014

- Messages

- 254

Those work great, but for facing to length, you will end up cutting grooves in them. Those are more for turning OD's. They will keep things round and concentric. Used many, made quite a few.

You can set the part just over the edge of the mandrel to face. We do it all the time with a certain part at work.

- Joined

- Jan 22, 2011

- Messages

- 8,031

When I used them (for the parts I have in my mind at the moment) we had to have a +0.0005/-0.0000, so we used a groove tool and never moved them. Just skimmed one end and dialed over the dimension plus the insert width and shot right to it. You can also turn a shoulder on them to hold them at the same place all the time. Like Wreck said, they are considered consumable. They aren't costly, and can even be shop made if you've a mind to.

- Joined

- Jul 17, 2013

- Messages

- 99

Use a collet of the correct size and it won't deform. With collects, you don't need as much pressure to hold it because it has 360* support

I would like to add a collet chuck.. Seems like it'd be pretty handy.