- Joined

- Feb 12, 2014

- Messages

- 53

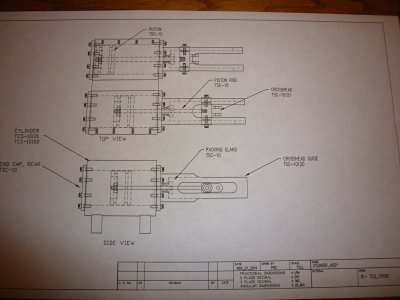

Had to put the Atlantic locomotive on the shelf for a while so in the mean time I decide to start building a stationary two cylinder reversing steam engine I drew up last winter. So far I have the cylinders bored but not yet honed, the crosshead guides are machined, valve plates are done and I have the parts for the crankshaft machined. Hope to get the crank silver soldered up this week and move on to other parts. I think it should work out OK, I will use walchert reversing gear, on paper all looks well, but then there is reality. Time will tell

Regards

Pat

Regards

Pat