- Joined

- Jun 12, 2018

- Messages

- 712

I took video footage of the two issues I currently have with my Grizzly 7x12 mini-lathe that I got last monday. This is my first lathe ever.

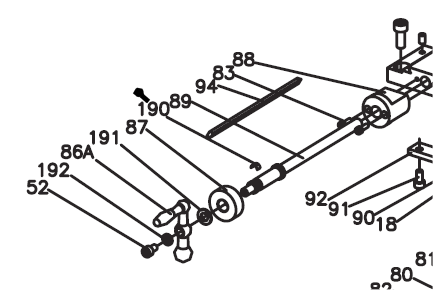

1st is the graduated collar on the compound slide doesn't turn with the handle. The allen screw is already super tight. I took the compound slide out and cleaned it, didn't see anything out of the ordinary, but this is my first time messing with this

2nd part of the video shows that I'm having problems facing off the work piece. The cutting tool ends up tapering the work piece and doesn't stay square. I've tried different cutting tools, different angles, different work pieces. I've been cutting off .005 to .030. It all ends up the same. with a rounded end of the workpiece.

1st is the graduated collar on the compound slide doesn't turn with the handle. The allen screw is already super tight. I took the compound slide out and cleaned it, didn't see anything out of the ordinary, but this is my first time messing with this

2nd part of the video shows that I'm having problems facing off the work piece. The cutting tool ends up tapering the work piece and doesn't stay square. I've tried different cutting tools, different angles, different work pieces. I've been cutting off .005 to .030. It all ends up the same. with a rounded end of the workpiece.