- Joined

- Feb 2, 2014

- Messages

- 1,061

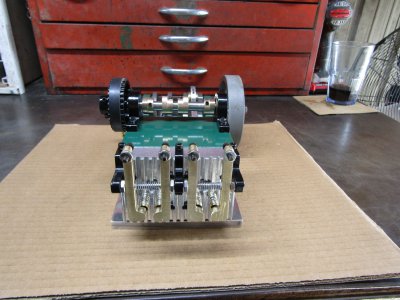

I made the valve spring retainers, cut the E clip grooves, and cut the valves to length.

Last night I spent 2 hours or so lapping the valves bu hand first with automotive valve grinding compound and then with some copper polish while watching the TV. The copper polish has worked very well for me in the past so fingers crossed. Time will tell if my work has been successful and the valves all seal.

Thanks for looking

Ray

Last night I spent 2 hours or so lapping the valves bu hand first with automotive valve grinding compound and then with some copper polish while watching the TV. The copper polish has worked very well for me in the past so fingers crossed. Time will tell if my work has been successful and the valves all seal.

Thanks for looking

Ray