- Joined

- Feb 2, 2014

- Messages

- 1,058

After I finished my crankshaft build last week I asked for ideas of an engine to build around it. There were no replies except for this.

I don't know what this engine will turn out to look like but I want to show off the crankshaft so area will be open.

I want to try my hand at water cooling the block using a radiator of some sort with a pump.

The stroke is already set at 1.500 and a bore of 1" is easy to work with so that is settled.

What about a timing belt instead of gears?

Maybe paint it red.

That where I am at now.

I started off with a block of aluminum and whittled it down to about the right size.

I milled the holes for the two piston sleeves with a lip around one end for the sleeve to bottom out against.

Size comparison with the crank.

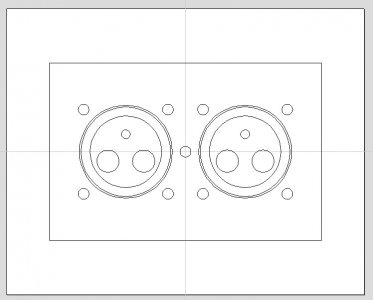

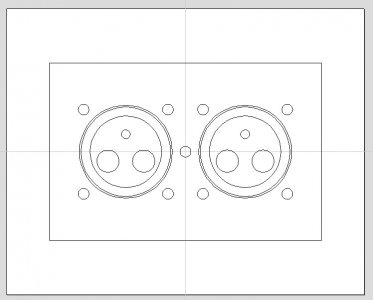

Now I usually don't make any drawings but I could see some problems already with the cylinder head bolts and the intake ports so I drew this up.

Now that doesn't tell you much but from that I am able to see where all the cylinder head bolts will go and if I have enough clearance for the intake and exhaust ports.

The hottest part of the cylinder liners I would think would be in the first 1 1/2" from TDC. I milled a slot 1" X 1 1/2" X 3" deep in the side of the block so that the water could circulate all around the liners. This slot will be covered with an aluminum plate that has the inlet water connection toward the bottom.

And a couple of more pictures.

While I was at it I drilled and tapped the head bolt locations.

I have never made an actively cooled block or head so I don't know how this will end up.

I am open to suggestions.

If you like what you see then leave a comment or at least give me a like.

Thanks for looking

Ray

Yes thank you Robert I was thinking along those lines myself.At least you know how many cylinders.

Robert

I don't know what this engine will turn out to look like but I want to show off the crankshaft so area will be open.

I want to try my hand at water cooling the block using a radiator of some sort with a pump.

The stroke is already set at 1.500 and a bore of 1" is easy to work with so that is settled.

What about a timing belt instead of gears?

Maybe paint it red.

That where I am at now.

I started off with a block of aluminum and whittled it down to about the right size.

I milled the holes for the two piston sleeves with a lip around one end for the sleeve to bottom out against.

Size comparison with the crank.

Now I usually don't make any drawings but I could see some problems already with the cylinder head bolts and the intake ports so I drew this up.

Now that doesn't tell you much but from that I am able to see where all the cylinder head bolts will go and if I have enough clearance for the intake and exhaust ports.

The hottest part of the cylinder liners I would think would be in the first 1 1/2" from TDC. I milled a slot 1" X 1 1/2" X 3" deep in the side of the block so that the water could circulate all around the liners. This slot will be covered with an aluminum plate that has the inlet water connection toward the bottom.

And a couple of more pictures.

While I was at it I drilled and tapped the head bolt locations.

I have never made an actively cooled block or head so I don't know how this will end up.

I am open to suggestions.

If you like what you see then leave a comment or at least give me a like.

Thanks for looking

Ray