- Joined

- Oct 14, 2014

- Messages

- 1,966

I will soon be helping my son build what I'll call the ultimate 3 phase converter. he has just built the ultimate shop for his life - a 30' x 40' super insulated building with in floor heat.

This will be the fifth rotary converter I've built over the last 25 years. There is a five year old post on the fourth one: https://www.hobby-machinist.com/threads/25hp-3pahse-conveter-with-load-center.26944/

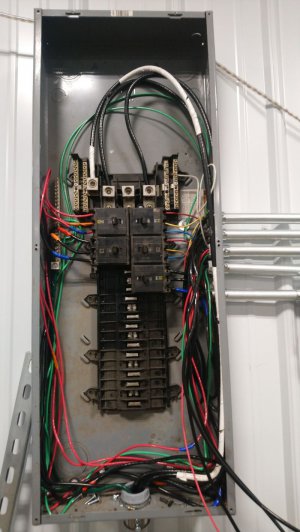

This unit will be similar to gen 4. Some features. It will use a 3 phase load center for all fusing. Each machine will have its own circuit breaker for this panel. In addition there are two idle motors, a 7.5 hp and 25 hp with each motor having its own circuit breaker.

Both idler motors have a motor starter in the converter panel. Also plenty of both start capacitors and run capacitors. Timers will be used to bring in motor1 along with start caps for motor1 then drop the start caps and bring in run caps for motor1. Another timer will then bring in motor2 a few seconds later. finally run caps for motor2 a few more seconds after that.

The unit will be set up so he can just turn off the circuit breaker for motor2 when smaller 3 phase loads are used - not use the larger motor at all.

A push to start, push to stop buttons will be used to start and stop the unit.

OK, today the kid just got the empty panel mounted. I told him get the power wiring done and then I'll come over and do the logic wiring and debug.

This will be the fifth rotary converter I've built over the last 25 years. There is a five year old post on the fourth one: https://www.hobby-machinist.com/threads/25hp-3pahse-conveter-with-load-center.26944/

This unit will be similar to gen 4. Some features. It will use a 3 phase load center for all fusing. Each machine will have its own circuit breaker for this panel. In addition there are two idle motors, a 7.5 hp and 25 hp with each motor having its own circuit breaker.

Both idler motors have a motor starter in the converter panel. Also plenty of both start capacitors and run capacitors. Timers will be used to bring in motor1 along with start caps for motor1 then drop the start caps and bring in run caps for motor1. Another timer will then bring in motor2 a few seconds later. finally run caps for motor2 a few more seconds after that.

The unit will be set up so he can just turn off the circuit breaker for motor2 when smaller 3 phase loads are used - not use the larger motor at all.

A push to start, push to stop buttons will be used to start and stop the unit.

OK, today the kid just got the empty panel mounted. I told him get the power wiring done and then I'll come over and do the logic wiring and debug.