Michael,

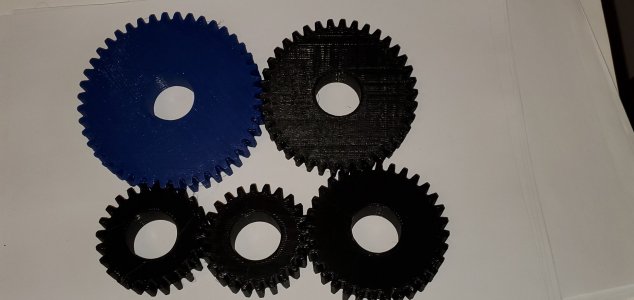

You may still decide to cut new gears yourself in steel or aluminum, but soon you'll have these plastic ones to use in the gear train to help.

They might just be a "stepping stone", but that's great!

Yes I do find this fun, and it does still amaze me that I can do this at home so easily.

Here are some pictures:

The printer starts with an outline and then fills it in.

The next layer is done in a different direction.

View attachment 441838

View attachment 441839

View attachment 441840

View attachment 441841

The printer is a Lulzbot Taz-6.

You can see some air bubbles under the surface layer of the heated table.

They have never caused any issue, so I ignore them.

The last gear is printing now, I will pile them up for a "family photo" later.

Brian