- Joined

- Jun 8, 2016

- Messages

- 603

I am very close to moving into my new shop space. When I do, I would like to upgrade my RPC for the lathe. First let me say that I don't find VFD's to be an option, call it bias, lack of experience, bad decisions or hard-headedness. I like the RPC and the ability to use the machine as built. For the record I am powering a single lathe, a Logan 12" with 2 speed motor and a really handy Reeves Drive, all this in a machine from the 1960's.

What I have now is a simple unbalanced RPC as detailed here MY RPC . I am using a 7.5hp 3ph motor as an idler, I have no caps to balance anything out. To start the RPC I wrap a small rope around the idler shaft and give it a pull to get it moving, then hit the switch and we're off.

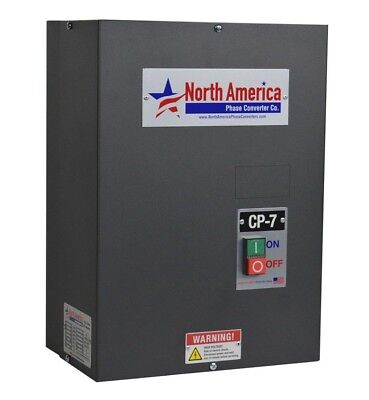

Now, what I would like to have when I move is an upgraded control panel. I would like to have a way to simply push a button and the panel start to motor and keep it going without me having to spin the motor manually. My question is how hard would that be to build myself, and would it just be worth it to buy a panel to hook up to my idler motor? If buying a panel, what brand(s) should I look for and which ones should I stay away from? At one point I thought one of our members made panels for sale, is the correct? If so who?

What I have now is a simple unbalanced RPC as detailed here MY RPC . I am using a 7.5hp 3ph motor as an idler, I have no caps to balance anything out. To start the RPC I wrap a small rope around the idler shaft and give it a pull to get it moving, then hit the switch and we're off.

Now, what I would like to have when I move is an upgraded control panel. I would like to have a way to simply push a button and the panel start to motor and keep it going without me having to spin the motor manually. My question is how hard would that be to build myself, and would it just be worth it to buy a panel to hook up to my idler motor? If buying a panel, what brand(s) should I look for and which ones should I stay away from? At one point I thought one of our members made panels for sale, is the correct? If so who?