Recently I upgraded my South Bend 9 lathe compound to a large dial. Now I am doing the cross slide. It is quite a bit different in design from the compound. I will be basing this upgrade on the procedure by Steve Wells and Ed Godwyn. However I am changing a few dimensions to suit my needs better. These upgrades are not too difficult and actually very forgiving. There are only a few dimensions that are critical. As with the compound, I will be making everything new so I can use the lathe by leaving the original assembly in tact until done.

I started by ordering some needed parts.

I ordered a new spline gear shaft from Steve Wells. This is a longer shaft than the original. I also ordered the thrust bearings. They were ordered from MSC as they were the only supplier that had the proper size bearings. The bearings are .375" ID and 11/16" OD. ( other suppliers had the bearing but with a 13/16" OD and this is too large). The 11/16" OD is necessary to match the gear shaft diameter.

I also got a piece of 7/16-10 LH lead screw to make the new screw with. ( Thank you to "jocat54" for supplying this for me.)

Next is to begin making the large bushing. It will be 2" diameter and longer than the original.

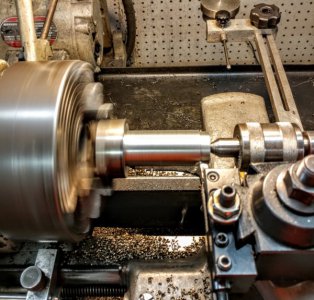

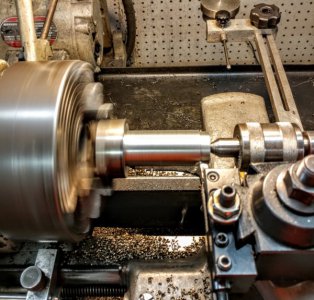

Machining the bushing shank down to .930" diameter the same diameter as the original)

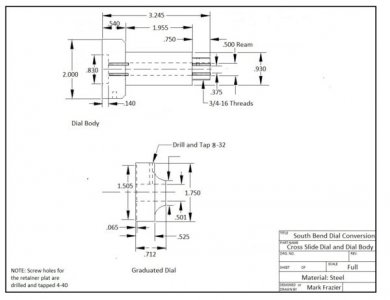

The first operation is complete and the 3/4-16 threads are put on while in this setup to be sure everything is concentric. Next the part will be turned around and put in a 15/16" ER 40 collet To do the boring, reaming and machining the bearing pocket and OD. This will insure that everything will be concentric (which is very important) as the ER collet is less than .001" TIR.

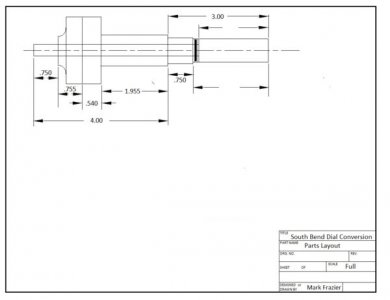

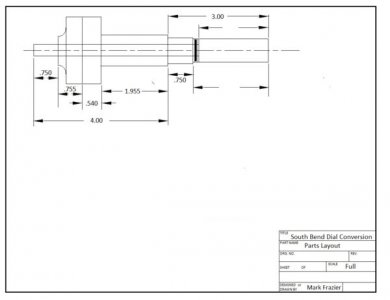

This is a parts layout diagram to be sure I maintain the proper dimensions. There are some dimensions missing which will be established and filled in as I go. I already made the graduated dial ( when I made the article about making these dials) and some dimensions are dependent on the actual dimensions of the dial.

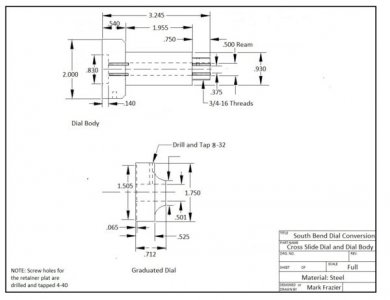

This drawing is the large bushing.

I started by ordering some needed parts.

I ordered a new spline gear shaft from Steve Wells. This is a longer shaft than the original. I also ordered the thrust bearings. They were ordered from MSC as they were the only supplier that had the proper size bearings. The bearings are .375" ID and 11/16" OD. ( other suppliers had the bearing but with a 13/16" OD and this is too large). The 11/16" OD is necessary to match the gear shaft diameter.

I also got a piece of 7/16-10 LH lead screw to make the new screw with. ( Thank you to "jocat54" for supplying this for me.)

Next is to begin making the large bushing. It will be 2" diameter and longer than the original.

Machining the bushing shank down to .930" diameter the same diameter as the original)

The first operation is complete and the 3/4-16 threads are put on while in this setup to be sure everything is concentric. Next the part will be turned around and put in a 15/16" ER 40 collet To do the boring, reaming and machining the bearing pocket and OD. This will insure that everything will be concentric (which is very important) as the ER collet is less than .001" TIR.

This is a parts layout diagram to be sure I maintain the proper dimensions. There are some dimensions missing which will be established and filled in as I go. I already made the graduated dial ( when I made the article about making these dials) and some dimensions are dependent on the actual dimensions of the dial.

This drawing is the large bushing.

Last edited by a moderator: