I started cutting aluminum plates on my radial arm saw many years before I heard how dangerous it was. I needed some smaller

chunks of 1/2" 6061 alum plate and didn't want to have to order it precut to size. I had a carbide toothed metal cutting blade

that I got for cutting some 1/8" brass plates for a kitchen cabinet I was making. I figured out that climb could be a (dangerous) problem,

and decided to cut from the front of the plate, pushing the saw back instead of pulling it forward.. I clamped the plate to the table on

both sides of the cut with 2X4's both on the front edges and on the top of each plate thus holding it against the back fence and

downward against the table. I started with very light cuts with the blade making only about 1/16" groove along the top surface.

I then slowly increased the cutting depth for each cut finally arriving at taking about 3/16" with each cut. I was amazed at how easy

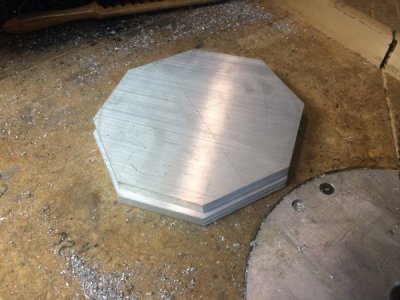

and quick it was to cut 10" x 10" pieces out of the 1/2" plate. After figuring out the setup, it went very quickly, the thing that took

the longest was getting all the clamps on and off for each piece. I've attached a few pictures of this to show the complete operation

including the great edge finish that I got. My biggest safety concern was the possibility of loosing a carbide tooth from the blade, so

I made sure that I wasn't standing in front of the saw. So although some say it's very dangerous, I say that you can make it as safe

as most shop operations if you use your noggin an take it slowly.

.