- Joined

- Oct 14, 2014

- Messages

- 1,970

dunno why, but I keep thinking how I would make five or ten cranks using a lathe to do the finish work. If I am just being a pain in the behind, ignore me.

Using both a mill with six index points and a lathe with four different centers causes real setup issues. Especially if you want to be accurate AND quick.

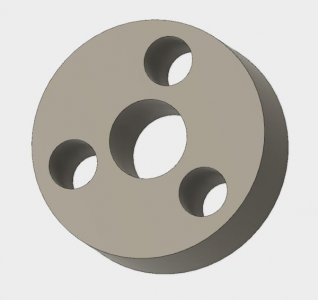

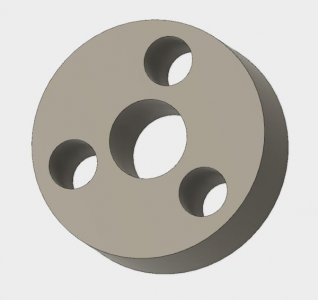

My solution would be a fixture for each end. Assuming 3 cylinder, the throws are 120 degrees apart. (Fours cylinder is actually easier cause you got two pairs 180 degrees apart) I quickly modeled a concept of what the fixture would be for three cylinders. Mount one of these on each end of your raw stock. The center hole is for locating in the index head on the mill, use the three outer holes to locate for indexing.

Next turn between centers in the lathe. Center holes do the mains. outer holes do the cylinder rod bearings .

.

Using both a mill with six index points and a lathe with four different centers causes real setup issues. Especially if you want to be accurate AND quick.

My solution would be a fixture for each end. Assuming 3 cylinder, the throws are 120 degrees apart. (Fours cylinder is actually easier cause you got two pairs 180 degrees apart) I quickly modeled a concept of what the fixture would be for three cylinders. Mount one of these on each end of your raw stock. The center hole is for locating in the index head on the mill, use the three outer holes to locate for indexing.

Next turn between centers in the lathe. Center holes do the mains. outer holes do the cylinder rod bearings

.

.