Yes. R8 collets have a keyway and the spindles have an alignment screw, basically just a setscrew with a square tip. The screw is just there to keep the collet/tool from rotating while the drawbar is tightened; the taper is what does all the work to keep the collet/tool from rotating inside the spindle during use. Your spindle should work fine without it, but you need to be careful to keep the spindle and tool very clean and take pains to keep the tool from rotating and galling the spindle as it's tightened.

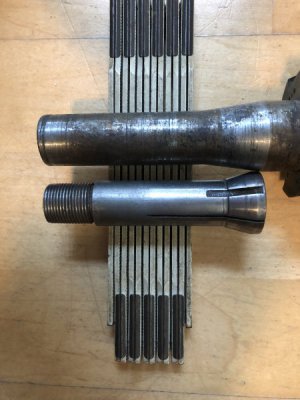

Your spindle looks very rough inside. I don't know how well the taper will hold, particularly with that big slab mill. When you get a new R8 tool (preferably an endmill holder, not a collet), used high spot bluing to locate and remove the high spots in the spindle until you get good contact between the tools and the taper. A round-tipped scraper would be the best thing to start with. I have some round-tipped scrapers that I got from either Enco or MSC, but I'll be darned if I can find any for sale now. Push comes to shove, you can grind your own scraper from old files. Ideally, you would like to have the spindle professionally ground, but there's no harm in trying to improve things by hand.