- Joined

- Sep 3, 2011

- Messages

- 478

Here's some additional information about the table oil passages:...

There are over 20 places that need lubrication with way oil. ... The one for the table ways is on the front of the table itself, near the middle:

View attachment 273567

You should see oil coming out on the sides of the saddle, below the ways in front and in back. If not, something is plugged up.

...

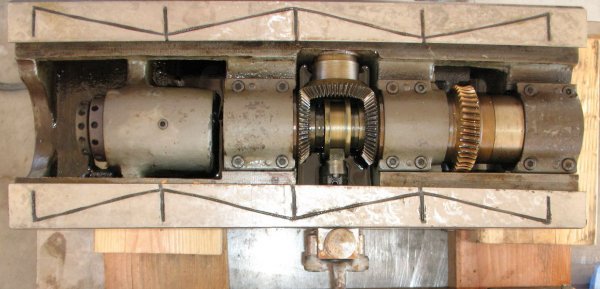

As mentioned before, the oil point for the table (X-axis) is a hole in the front of the table, capped by a slotted, flat-head screw with the word "OIL" stamped on it. Behind the screw is a horizontal passage, drilled from the front of the table towards the back. Two vertical cross holes, drilled upwards from the front and back flat ways, intersect the horizontal passage. This photo shows the bottom of the table with the location of the horizontal oil passage marked in red. (The front of the table is towards the bottom of the frame):

Here's a close up of the front of the table, looking up from below:

(The front of the table is at the top of the frame.) The oil inlet is visible at the top of the frame. Note the vertical oil hole and transverse slot that is machined into the bottom of the front flat way. A matching hole and slot are machined into the table over the rear flat way.

Here's the X-axis ways on the top of the saddle:

Note the five transverse slots machined into the both ways and the diagonal slots that connect them. These slots serve to collect and distribute the oil from the two oil slots in the table above. Also observe how the three slots in the middle, front and rear, are open to the center to allow oil to migrate to the dovetail ways and on to the center sump. It should be obvious that there is no reservoir to store oil for the table ways, apart from the passages and slots already mentioned. This is why the table should be lubricated each time the machine is used.

Every so often, perhaps once a week, the table should moved back and forth to distribute oil to the full length of ways: Crank the table all the way to one end and squirt way oil into the fill point on the front of the table until it appears on the saddle on both sides, front and rear. (I like to use a small plastic squeeze bottle with a pointed tip for this.) The table should then be cranked all the way to the other end and the process repeated. While the table is at either end, it's a good time to squirt or brush oil onto the exposed leadscrew. Once the table is returned to center, wipe of the excess oil from the sides of the saddle.