Would say there are a number of different opinions on the subject. There is quite a bit on the internet advising the use of shielded VFD cable. The manuals consistently state to use VFD cable, this is geared toward electrical noise radiation, country requirements, etc. but more specific toward commercial use. My general take on the matter is if the cable is short 3-4' feet, I do not use shielded cable but beyond that I do. There are several factors, first is interference with the control wires, and also the speed pot. It is good practice to keep these cables at least 4-6" apart if running in parallel. I have seen the VFD electrical noise being picked up in the speed cable and also tach cable, so I do shield these cables and terminate them per the manufactures recommendation. Also I have had a few individuals that I worked with who had TV and Radio interference from the VFD. It may or may not mitigate the use of EMI/RFI filters, it will have no effect on electrical noise on the voltage input side, you can purchase a noise filter if there is a problem. On the output side most people do not use filters on the motor cable, you can use ferrite ring or a sine wave filter. I have used the former, but not the latter. In most cases at the hobbyist level, I would say not necessary to have an EMI/RFI filter. There is one exception, if you are using a 3 phase input VFD and powering it with single phase and derated as such, it will a generate a lot more THD into the input circuit and also much larger current draw spikes. In this case almost every VFD manufacture specifies a DC choke on the VFD buss. An electrical noise filter may be needed on the input voltage side. My mill has one, my lathe I purchased one but didn't have the room to install it. I still may add it at a later date.

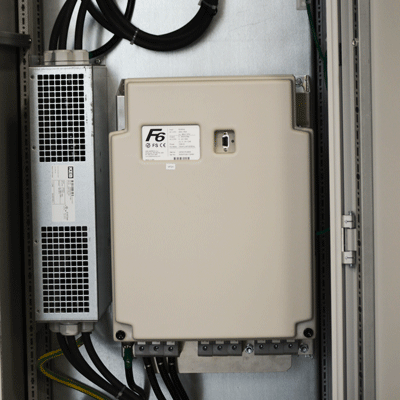

Learn the basics of EMI and the top seven steps to reduce the effects of EMI noise in VFD applications. Using low leakage EMI filters like the E6 is best practice.

kebblog.com

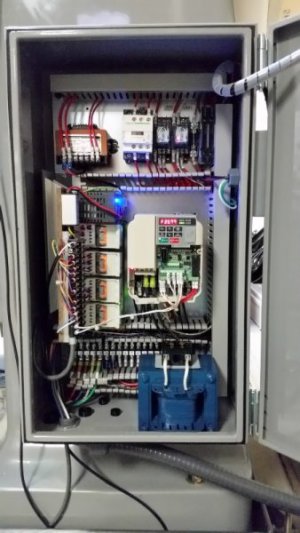

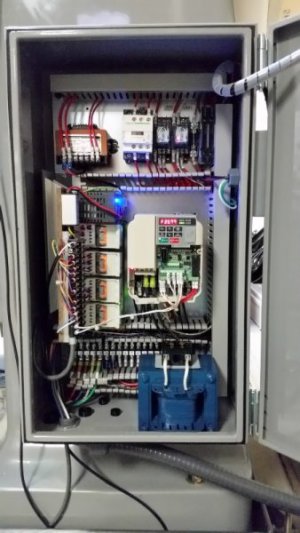

On both my mill and lathe I am using a Yaskawa 3 phase input VFD derated to use either single or 3 phase input, both use DC chokes and also shielded motor cable. The choke is in the lower right corner. The cables shield grounds are all connected to a common buss that is attached to the metal back panel. Electrical noise can be a significant issue, but not always predictable as to what or how it is going to interact with other components and if following the manufactures recommendation actually is correct. A bit of a grey area. Moving to CNC, this can also be a significant issue.

The other factor is the type of insulation needs to be able to withstand higher voltage spikes because of the nature of the signal is chopped spikes of DC voltage. So for 240V, I suggest a minimum of 600V cable. Lots of information on the net specific to this, a good SOOW cable ? or if pulled wire in flex tube one can use something like THHN/THWN. When I build VFD systems, I always use shielded VFD rated cable, just figure you are spending a good amount and the cost difference is maybe $15-20 to purchase shielded VFD cable. You ales need to insulate the shield and tie it to the ground wire at both ends for only the motor cable, all other cables only at the VFD end. Typically I use a star ground in the VFD enclosure for all the grounds. Also note that for 2 and 3 Hp motors you would use 14 AWG wire cable, it is 3 phase and the current is less.