- Joined

- Jul 8, 2018

- Messages

- 880

I've been rebuilding a benchtop bandsaw (9" Duro) and it's now at the point where I need to hook up a motor.

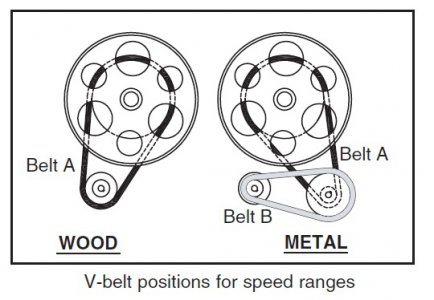

I know I can get metal-cutting speeds with a suitable gear or pulley arrangement. I was reading up on using a DC motor with a variable-speed control (RVP Precision has an article and a thread here), and the price for the controller is not that far off a cheap VFD.

Would using a VFD on a 3/4 or 1 HP motor provide sufficient torque for cutting steel? Using a cheap 3-phase motor, the cost would be about the same as a DC with variable speed control. More expensive than pulleys (and presumably less torque), of course, but a convenient way to change speeds would be nice if it doesn't degrade the power of the saw too much.

I know I can get metal-cutting speeds with a suitable gear or pulley arrangement. I was reading up on using a DC motor with a variable-speed control (RVP Precision has an article and a thread here), and the price for the controller is not that far off a cheap VFD.

Would using a VFD on a 3/4 or 1 HP motor provide sufficient torque for cutting steel? Using a cheap 3-phase motor, the cost would be about the same as a DC with variable speed control. More expensive than pulleys (and presumably less torque), of course, but a convenient way to change speeds would be nice if it doesn't degrade the power of the saw too much.