-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

VFD for rpm increase?

- Thread starter rjredline

- Start date

- Joined

- Nov 23, 2017

- Messages

- 1,191

A VFD will only decrease the input frequency from 60Hz down to 0Hz. That will only make your lathe run slower.

Edit: I didn't know there were VFD's that push more than 60Hz. I love google sometimes. More rpm = less torque.

http://www.electriciantalk.com/f28/running-motor-vfd-past-its-hertz-rating-19715/

Edit: I didn't know there were VFD's that push more than 60Hz. I love google sometimes. More rpm = less torque.

http://www.electriciantalk.com/f28/running-motor-vfd-past-its-hertz-rating-19715/

Last edited:

- Joined

- Jun 26, 2014

- Messages

- 619

More rpm = less torque.

Not necessarily. In an induction motor torque is related to slip - the difference in speed between the rotating magnetic field and the actual rotor rotational speed. A good VFD should be able to give near full torque at any speed from standstill to well over rated speed.

I don't think the motor will be the limiting factor, it will be the spindle bearings. If the original motor/pulley combination could only do 500rpm then likely the spindle bearing were only designed for 500rpm.

Last edited:

- Joined

- Feb 2, 2013

- Messages

- 3,622

the motor can take 90 Hz or slightly more for short periods of time without damage, that equals about 750 rpm

- Joined

- Oct 18, 2016

- Messages

- 2,872

Another consideration is whether your motor's windings are VFD rated (for temperature). Older motors usually aren't.

- Joined

- Apr 30, 2015

- Messages

- 11,252

It's temperature and also dielectric breakdown. Variable frequency drives generate voltage overshoots/spikes that can exceed the breakdown

rating of old insulation- modern "inverter rated" motors use heavy Formvar or Mylar insulation to protect against this.

Mark

rating of old insulation- modern "inverter rated" motors use heavy Formvar or Mylar insulation to protect against this.

Mark

- Joined

- Jun 16, 2016

- Messages

- 221

A new inverter-rated motor rated for 60hz/1725rpm will be quite comfortable at 120hz/3450rpm. After all, the bearings are most likely the same as in the equivalent 3450rpm motor, and they've likely balanced the rotor on the same equipment at the same speed. Your motor might not be, let alone your lathe.

- Joined

- Jun 12, 2014

- Messages

- 4,806

A good VFD should be able to give near full torque at any speed from standstill to well over rated speed

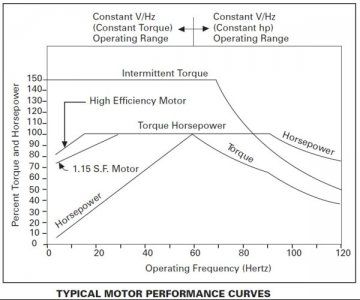

Torque falls off above a motor's base speed because the V/Hz ratio cannot be maintained above the motors base speed. So torque falls off in a somewhat non-linear fashion above this point for standard motors. What is not often factored in is that a machine with a fixed speed motor, to achieve the same machine spindle speed needs to be geared/belted up and thus torque is reduced based on the change in motor to spindle ratio. There are some variations on this where you have a dual voltage motor, say 230/460, you wire it for 230 but run the VFD to 460V. BLDC and other motor variants may also be able to maintain full torque within the operating design of the system. Hp falls off in a linear fashion below the base speed, one reason why VFD machines often oversize their motors vs. a comparable geared fixed speed motor machine. VFDs can also boost torque/current to the motor for short periods of time, so you will often see 150% boost for 1 minute. An older motor should be set to 100%. The speed range that a motor can maintain torque below it's base speed varies by motor design. Typical older motors might have a 2:1 constant torque ratio so 30-60Hz, newer inverter rated motors maybe 10:1 so 6-60Hz, and vector motors have a 1000:1 or greater so full torque down to 0 RPM.

Most VFD have an upper frequency range of somewhere in the 400Hz range, but for all practical use with a 1750 RPM motor one should stay with an upper frequency of around 90-100Hz. This has more to do with performance fall of above this frequncy as opposed to motor bearings. A newer 3500 RPM motor, I would not exceed 70-75Hz. Vector motors can maintain full Hp up to their maximum operating speed, for a 1750 RPM motor this is usually around 6K for motors 3Hp and smaller. As others have mentioned, older motors/insulation do not do well with the voltage spikes generated by VFDs, and also the higher carrier frequency which generates more heat. There is also a difference if the motor is a dual voltage motor, such as a 230/460, since the factory wire insulation is able to better handle the voltage spikes if run at 230V. Too maintain the longevity of an older motor the carrier frequency should be kept at 2kHz, and I probably would not exceed 75Hz as an upper limit, a newish motor than maybe 90Hz for short periods. There are VFD motor filter chokes which can tame the voltage spikes, they tend to be expensive, but you can pick one up used or NOS for a fraction of list. On an older motor I would run it in a V/Hz setting as opposed to sensorless vector.

- Joined

- Apr 30, 2015

- Messages

- 11,252

Pretty much covers it, good tutorial

Mark

Mark