- Joined

- Jun 13, 2015

- Messages

- 97

Awhile back I had posted how much I liked Mark's (mksj) VFD install on his lathe. Mark PM'd me and, long story short, after a few emails back and forth he decided he would do me a huge favor and offered to build a system for my lathe.

Yesterday that build arrived in the mail. When I first opened the package I was floored. EVERYTHING was neatly and carefully packaged up. The instructions that came with it were superb to say the least. It was basically like connect the dots!

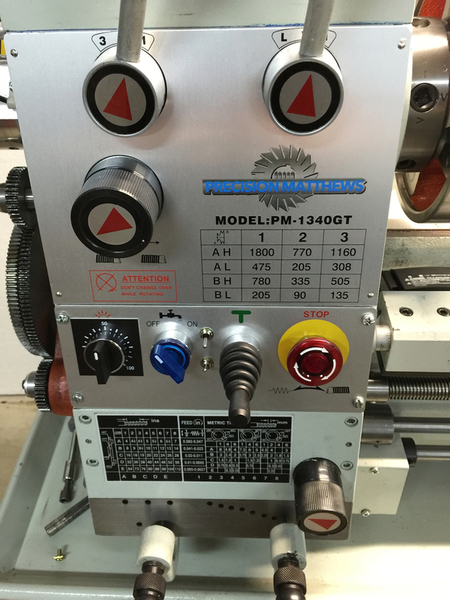

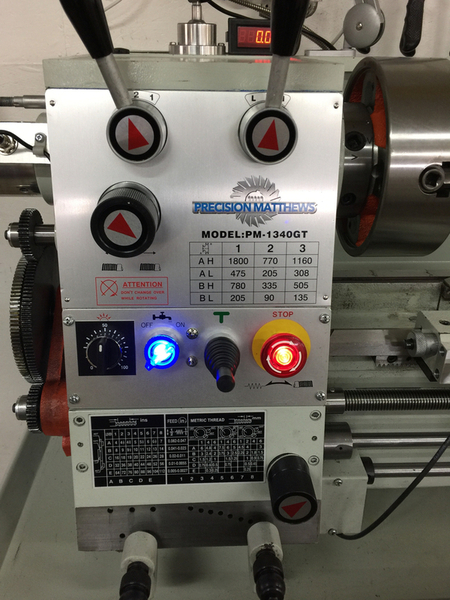

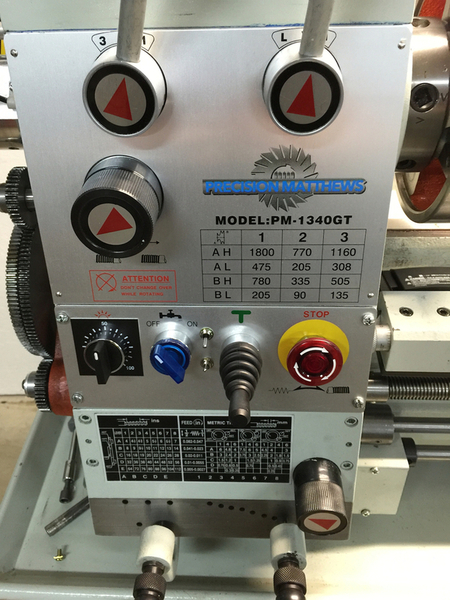

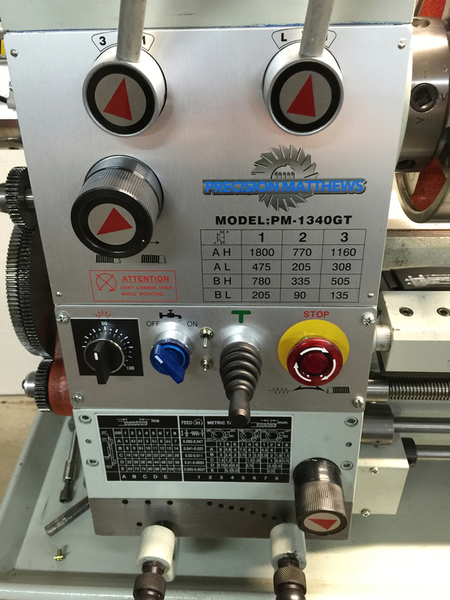

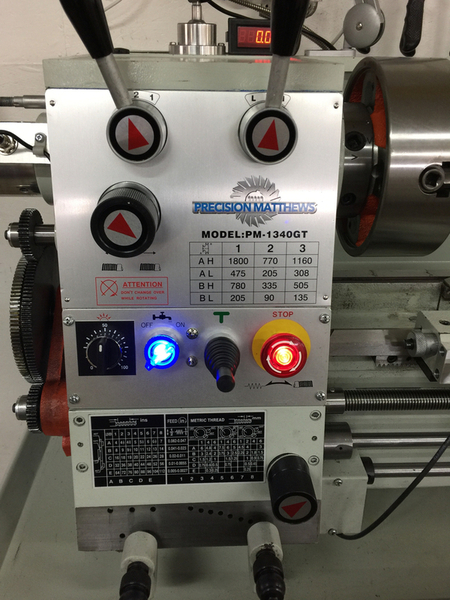

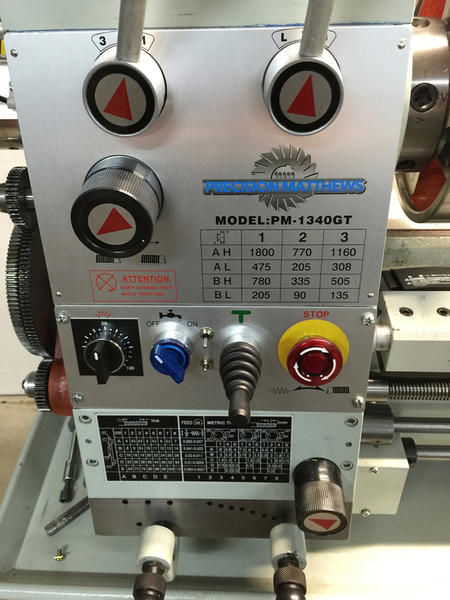

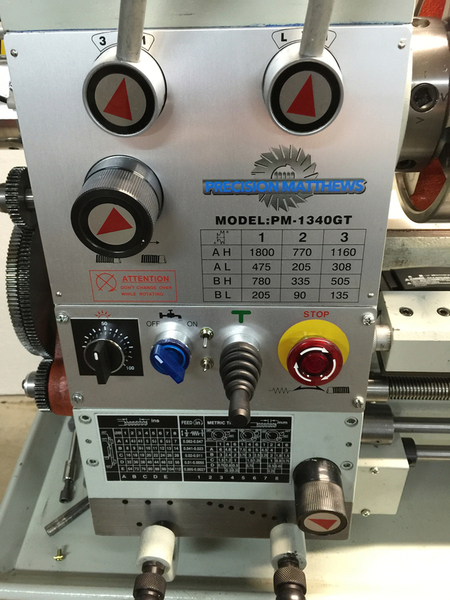

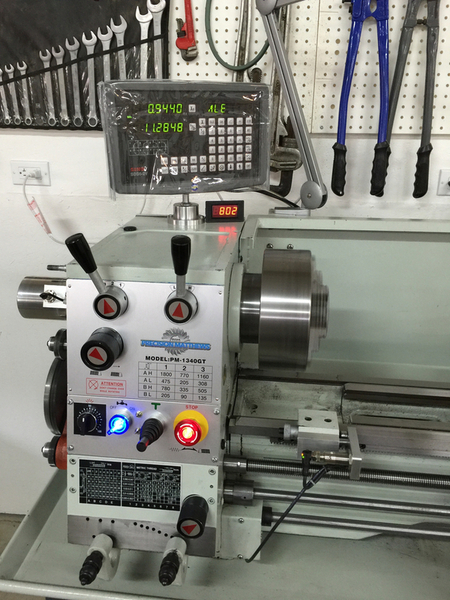

I spent most of the first day reading and getting a better understanding of the install. All I had accomplished on the first day was the control panel on the front of the lathe installed.

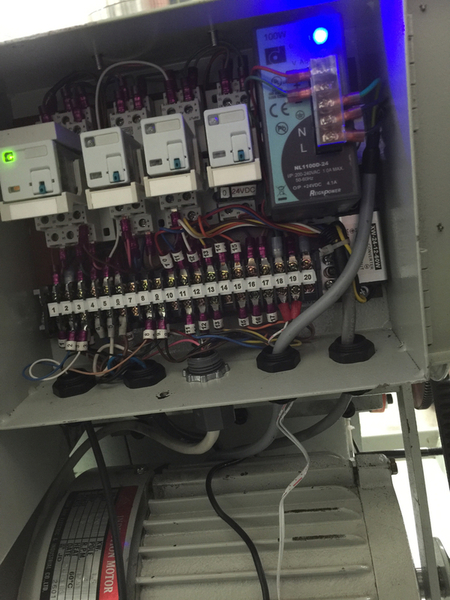

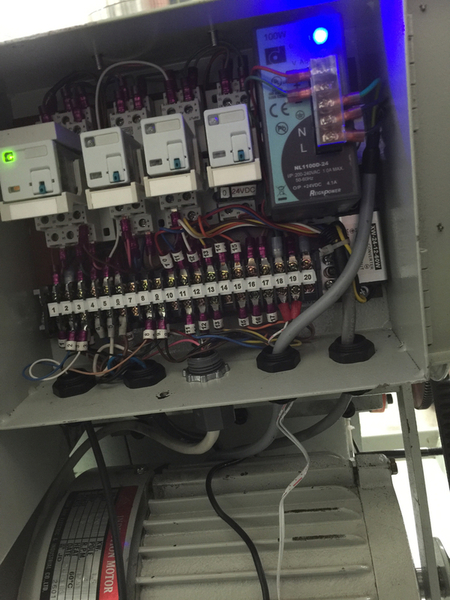

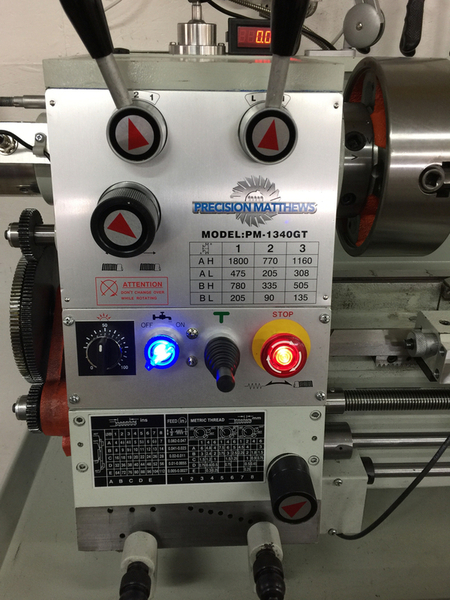

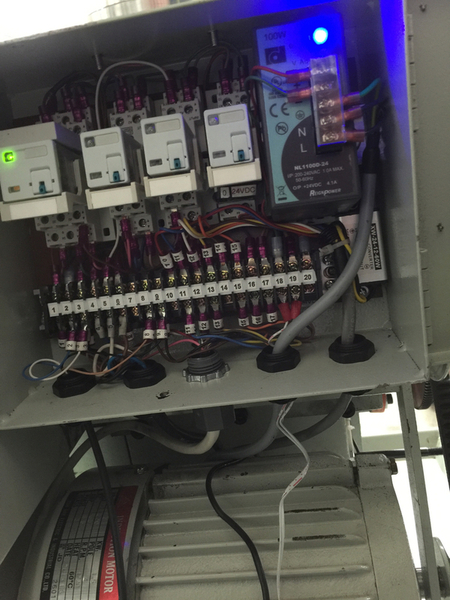

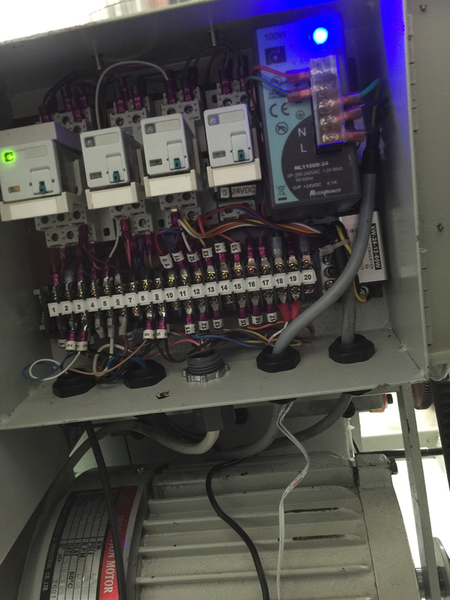

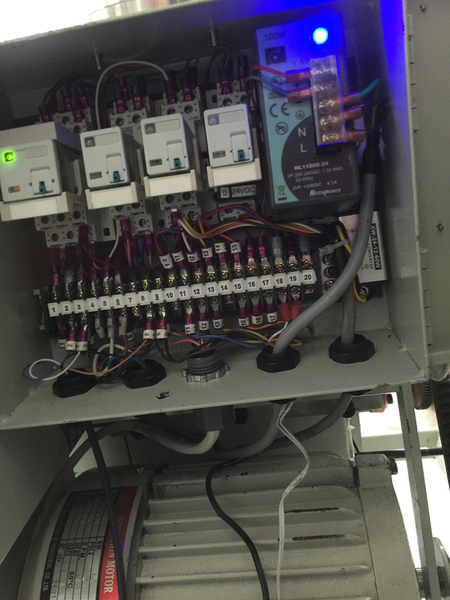

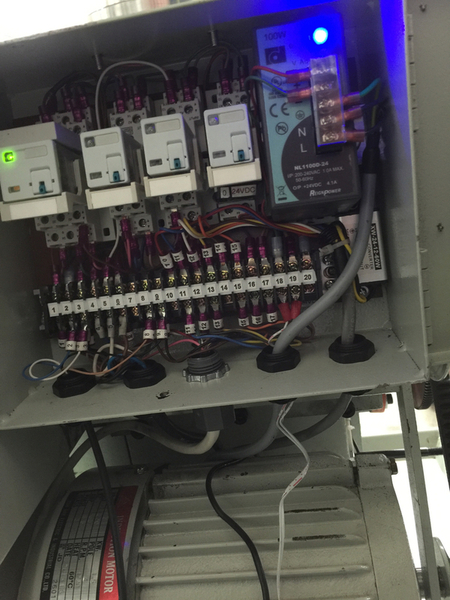

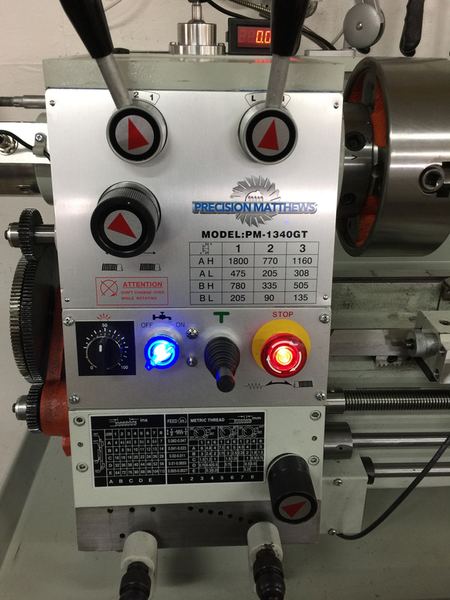

Today, I got a good jump on it and had all the factory electrical in the lathe tore out and VFD (Hitachi WJ200) installed in the top cabinet by noon. Getting the actual VFD mounted was most of the battle. Everything else just fell into place. The new electrical panel bolted right in, all I had to do was put in the 24VDC 100 watt power supply. Here it is all powered up. You can see how well marked the power connections were. SUPER easy to get everything hooked up where it was supposed to go!

Here's a few more pics of the install;

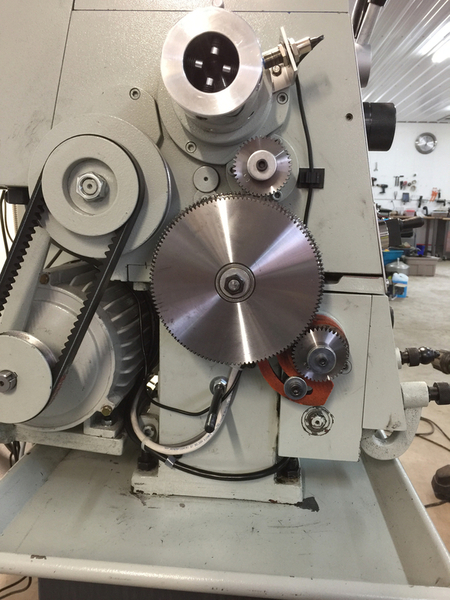

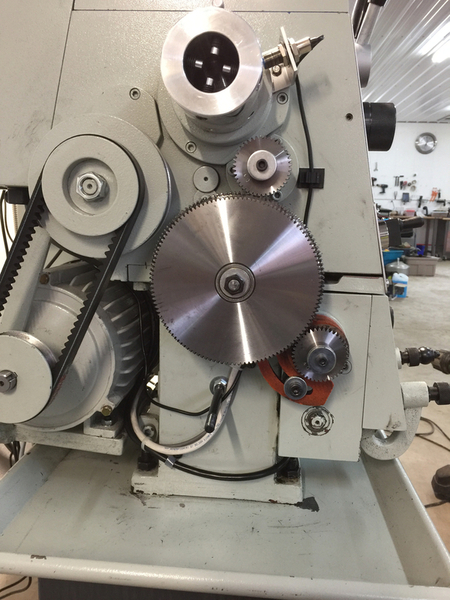

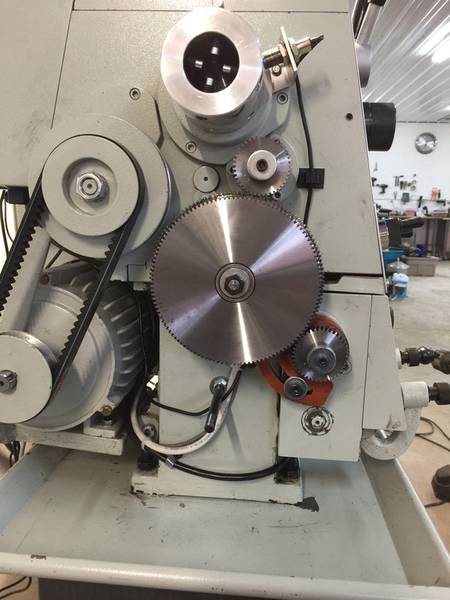

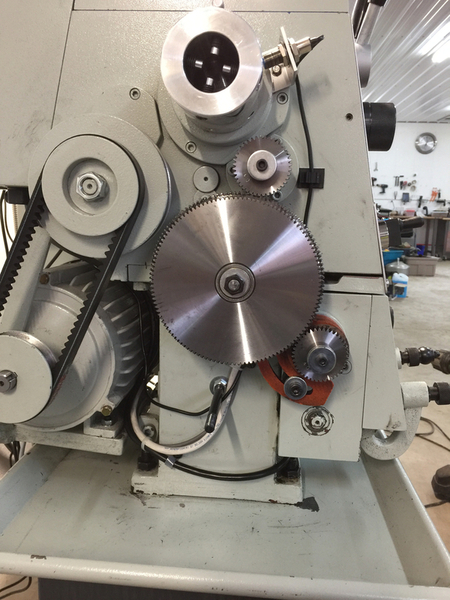

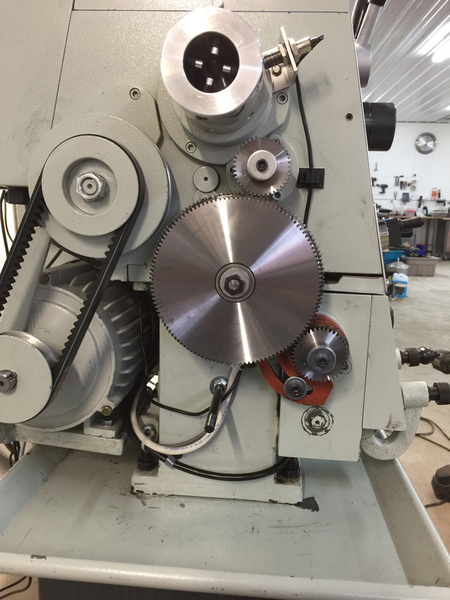

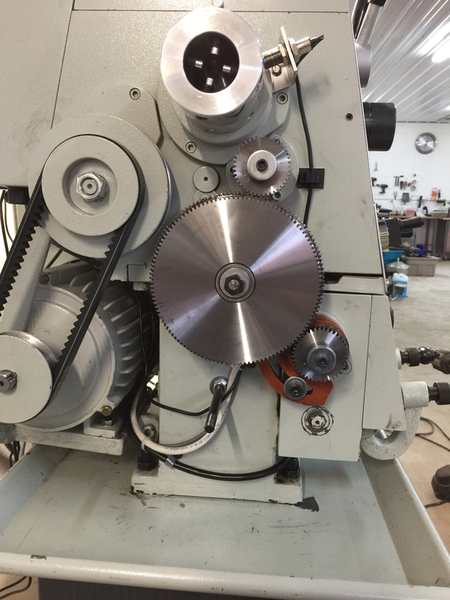

Wire routing from control panel through gearing to electrical panel. I just used the ties that were already on the lathe.

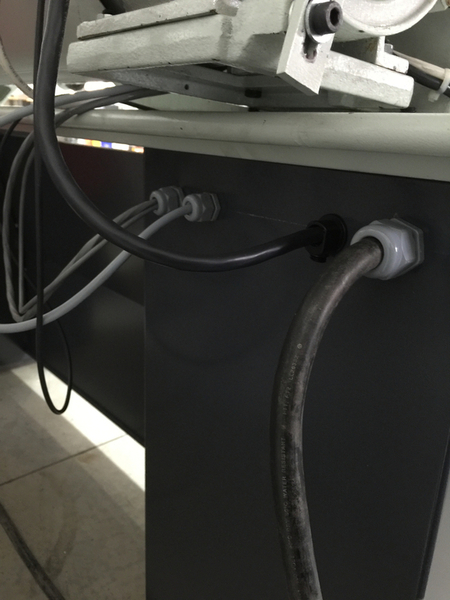

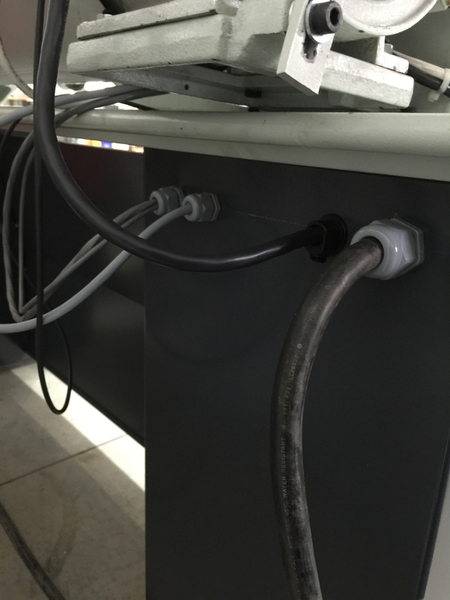

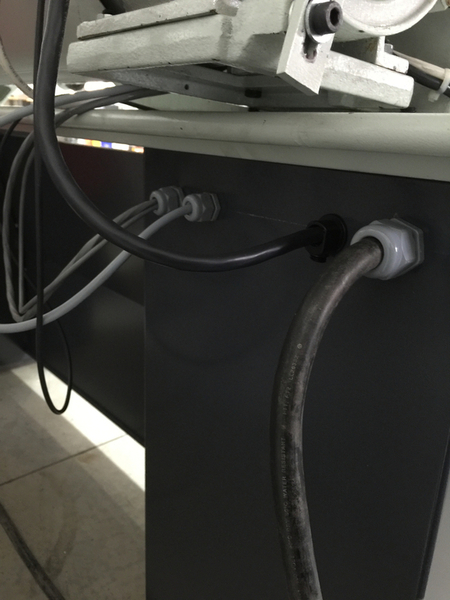

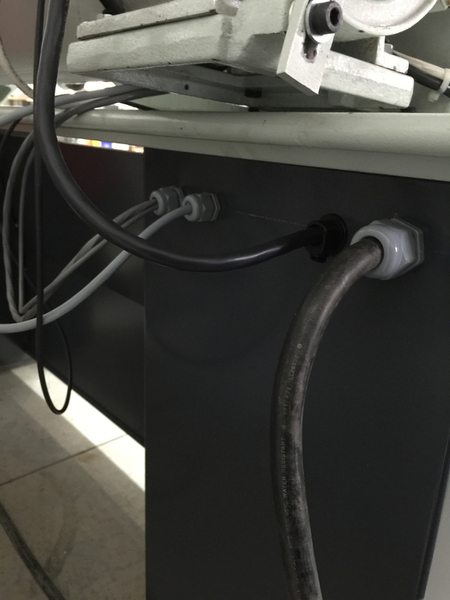

Wires leading into cabinet where VFD is mounted. Main power and motor wires on right and everything else from VFD to control/electrical panel on the left.

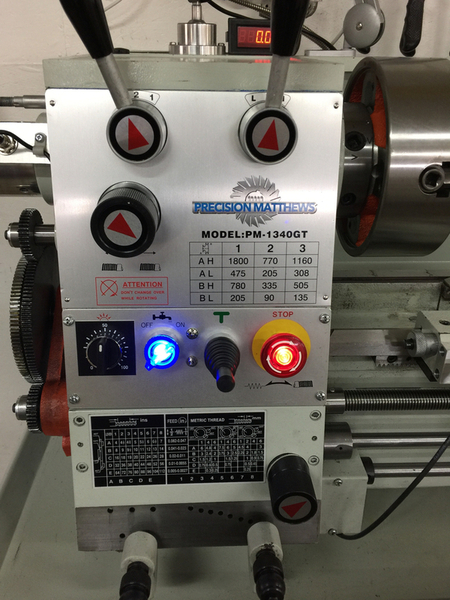

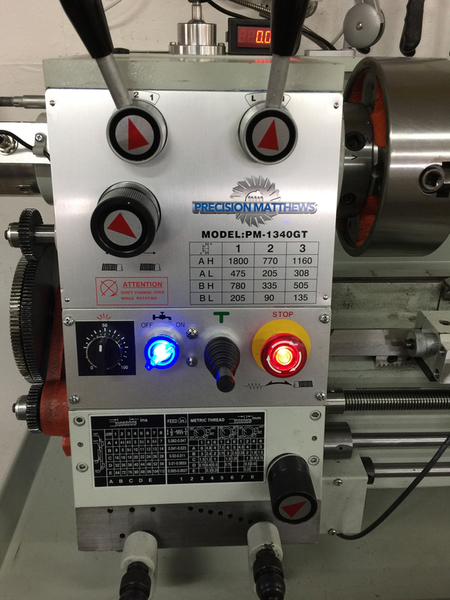

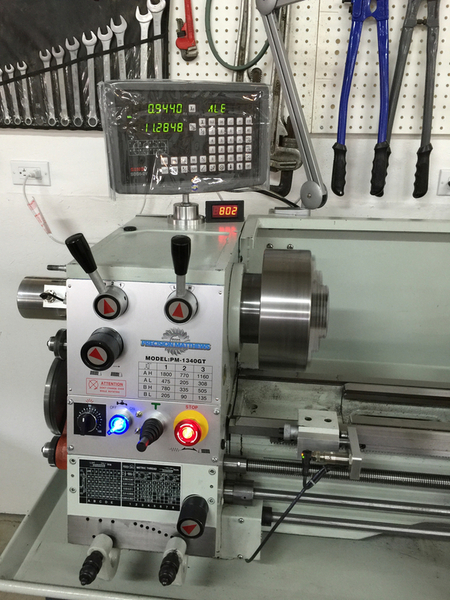

Lathe at first power up.

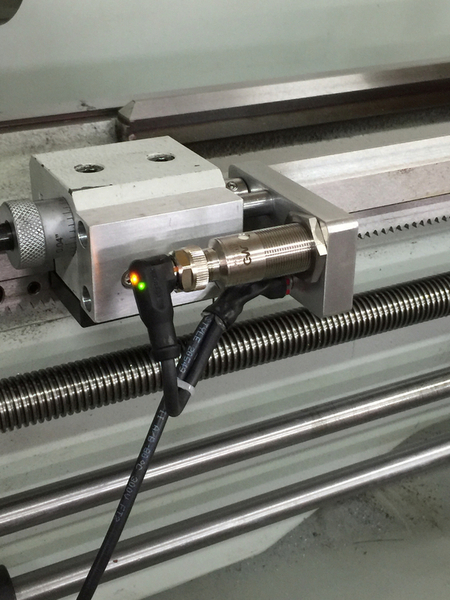

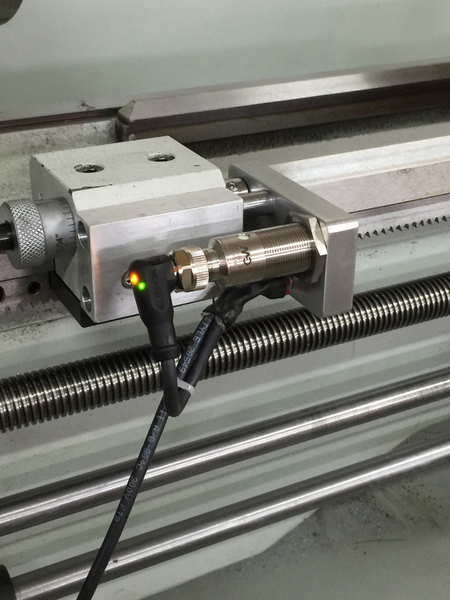

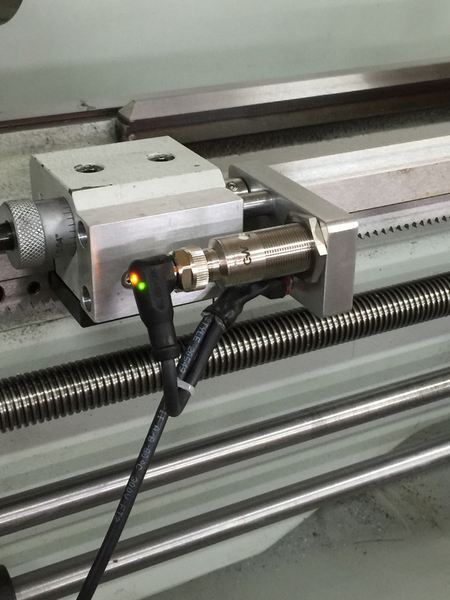

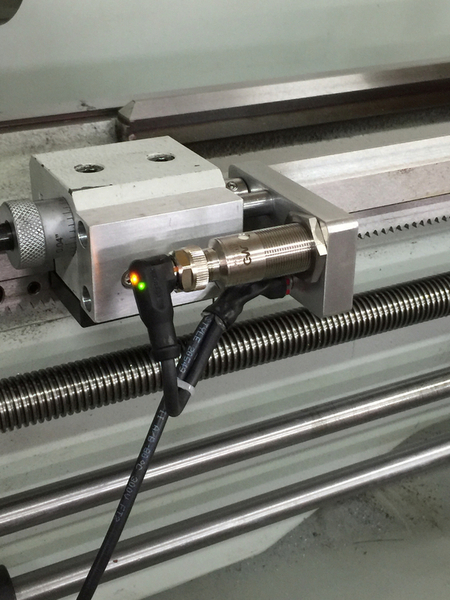

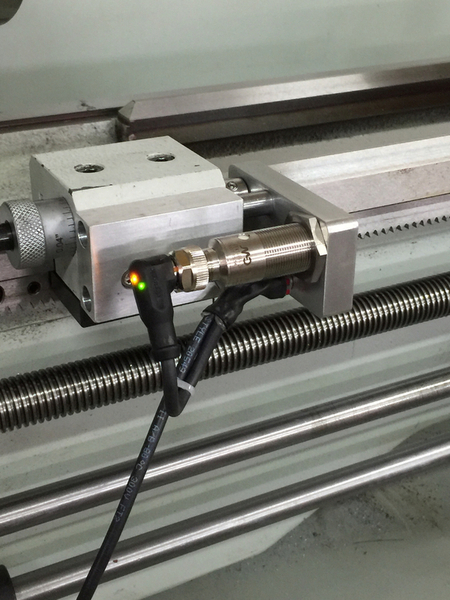

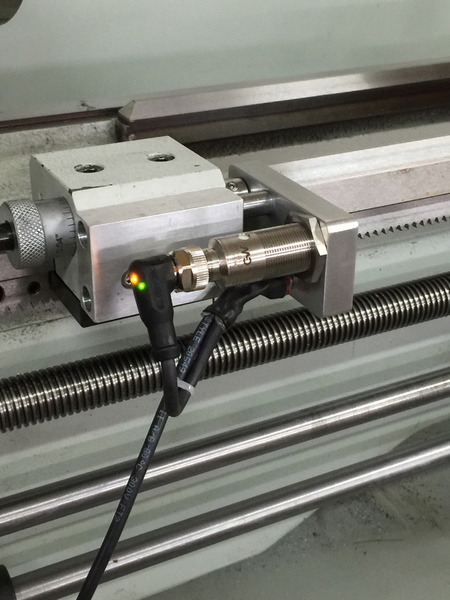

Proximity sensor installed. (installed before initial start up)

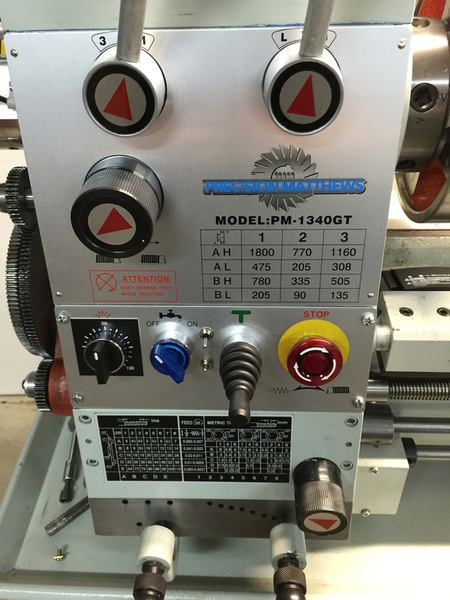

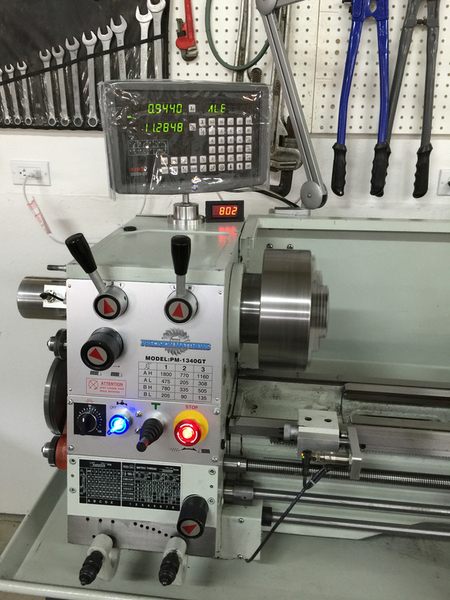

And finally, after programming the VFD, lathe up and running! I followed the instructions as per Mark and the lathe powered up without any hiccups.

I put the lathe through a few paces before calling it a night. The braking is awesome, stops the lathe dead in a second or better. The proximity sensor was accurate to 0.0001" each and every time!

A HUGE thank you out to Mark!

His talent for building these systems is incredible. There is no way I could have ever built a system this complex nor one that runs the lathe so smoothly.

*Mark, I'll get that proximity cable run under the chip pan tomorrow.

Yesterday that build arrived in the mail. When I first opened the package I was floored. EVERYTHING was neatly and carefully packaged up. The instructions that came with it were superb to say the least. It was basically like connect the dots!

I spent most of the first day reading and getting a better understanding of the install. All I had accomplished on the first day was the control panel on the front of the lathe installed.

Today, I got a good jump on it and had all the factory electrical in the lathe tore out and VFD (Hitachi WJ200) installed in the top cabinet by noon. Getting the actual VFD mounted was most of the battle. Everything else just fell into place. The new electrical panel bolted right in, all I had to do was put in the 24VDC 100 watt power supply. Here it is all powered up. You can see how well marked the power connections were. SUPER easy to get everything hooked up where it was supposed to go!

Here's a few more pics of the install;

Wire routing from control panel through gearing to electrical panel. I just used the ties that were already on the lathe.

Wires leading into cabinet where VFD is mounted. Main power and motor wires on right and everything else from VFD to control/electrical panel on the left.

Lathe at first power up.

Proximity sensor installed. (installed before initial start up)

And finally, after programming the VFD, lathe up and running! I followed the instructions as per Mark and the lathe powered up without any hiccups.

I put the lathe through a few paces before calling it a night. The braking is awesome, stops the lathe dead in a second or better. The proximity sensor was accurate to 0.0001" each and every time!

A HUGE thank you out to Mark!

His talent for building these systems is incredible. There is no way I could have ever built a system this complex nor one that runs the lathe so smoothly.

*Mark, I'll get that proximity cable run under the chip pan tomorrow.