Hoping someone could tell me if they have had any issue with vibration and their benchtop machine's bases.

My mill isn't to bad during cutting but the rapid had to be slowed down to about 200 ipm when the motors can easily run it at 400 ipm. The casters are removed and it is bolted into the concrete with a couple TEK Concrete screw. I am moving in a few months and didn't want to go overkill so I just kept is simple.

The lathe is unusable at 800 RPM, I assume I am exciting some natural frequency as it works fine at 600 RPM and 1000 RPM. The DRO bounces so much at 800 you can't even read it. The lathe isn't mounted to the concrete yet as I haven't finished building the feet. Before I put the feet on I wanted to make sure I didn't need any additional reinforcements.

Lathe PM1127

photos.app.goo.gl

photos.app.goo.gl

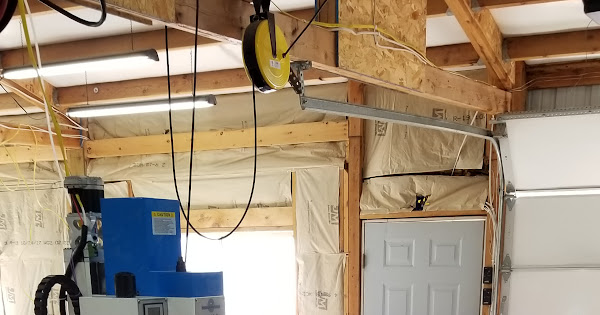

Mill PM30MV

photos.app.goo.gl

photos.app.goo.gl

Anyone else had similar issues? Did you stiffen up the toolbox to resolve the issue? The other thing I am considering for the mill is a A-frame from the column to the concrete but I could see getting it all adjusted right to be very difficult.

My mill isn't to bad during cutting but the rapid had to be slowed down to about 200 ipm when the motors can easily run it at 400 ipm. The casters are removed and it is bolted into the concrete with a couple TEK Concrete screw. I am moving in a few months and didn't want to go overkill so I just kept is simple.

The lathe is unusable at 800 RPM, I assume I am exciting some natural frequency as it works fine at 600 RPM and 1000 RPM. The DRO bounces so much at 800 you can't even read it. The lathe isn't mounted to the concrete yet as I haven't finished building the feet. Before I put the feet on I wanted to make sure I didn't need any additional reinforcements.

Lathe PM1127

New item by Casey Cotter

photos.app.goo.gl

photos.app.goo.gl

Mill PM30MV

New item by Casey Cotter

photos.app.goo.gl

photos.app.goo.gl

Anyone else had similar issues? Did you stiffen up the toolbox to resolve the issue? The other thing I am considering for the mill is a A-frame from the column to the concrete but I could see getting it all adjusted right to be very difficult.