- Joined

- Feb 2, 2013

- Messages

- 3,622

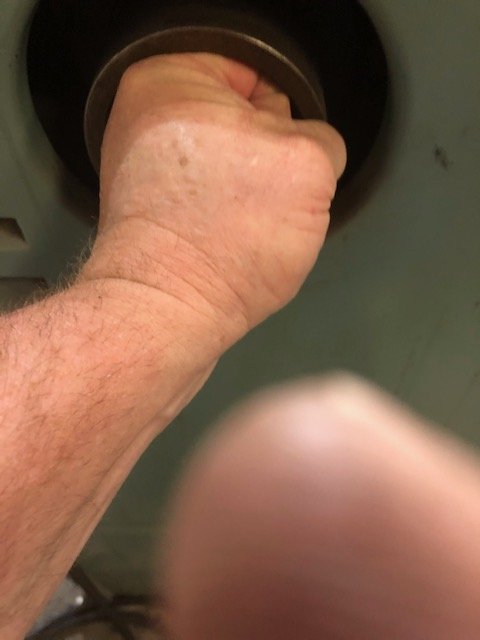

here is a shot from the distal end of the spindle looking thru to the chuck

one feature that is astounding to me, is the 80mm spindle bore

for reference,

i can almost fit my balled fist into the spindle bore

one feature that is astounding to me, is the 80mm spindle bore

for reference,

i can almost fit my balled fist into the spindle bore