U

umahunter

Forum Guest

Register Today

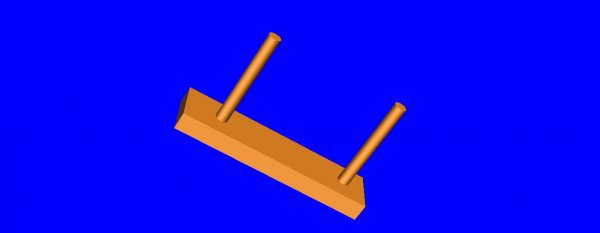

I'm looking for a thread I can't seem to find maybe I'm using the wrong words. I saw at one time a bar you clamp into your vise that lines up with flats on your mill column to quickly square your vise. i thought there was a video on it but now I can't seem to find pics the thread or video anyone make one or remember what I'm talking about. I'm doing a lil more each day as I recover and figured this is a lightweight project I could tackle thanks for any help