Here is the machine I bought. Picked it up in California. Overall I’m happy I have the machine. It will take months to refurbish due to my schedule. I am a little concerned about the way closest to the grinding wheels since the engraved grooves are very faint.

Does anyone know if Van Norman hand carved the grooves or if this was not factory?

On the bed ways there are moon shape grooves in the middle where the oil plungers make contact (similar to a lathe head stock oil plungers).

The lead screw for the grinding post has almost no wear from what I can see. I don’t believe the tail stock is original for the unit. I will need to measure and accommodate any height differences.

Will likely need a new coolant pump and new grinding motor (since it’s old and 3phase).

I have two manuals on way to help me dissect and operate the machine. The wheel crank for grinding wheels have 0.001” increments with a vernier scale for 0.0001” (0.0001-0.001”).

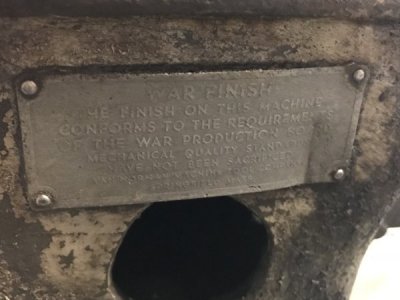

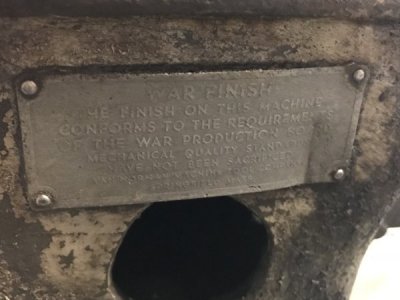

I have not found any serial numbers like my No 10 mill. Only indentification is the id tag stating meeting war requirements (which I think is cool).

As I progress through the machine, I’ll keep updating this thread.

If anyone has good ideas for a stand, please let me know. Wish it came with the original stand.