- Joined

- Feb 2, 2016

- Messages

- 55

Hi All,

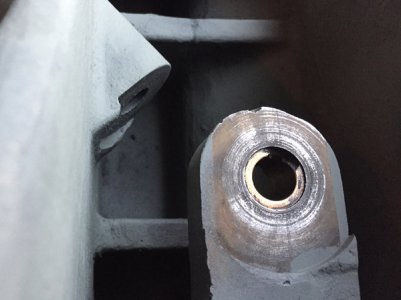

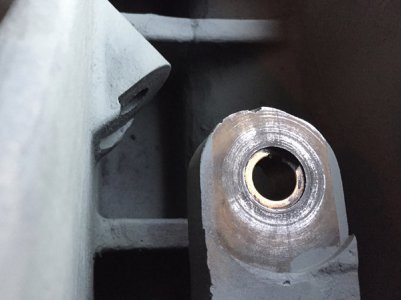

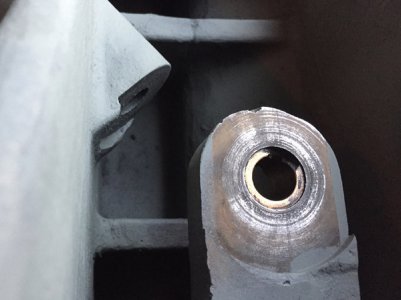

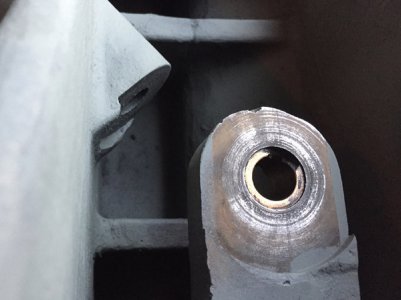

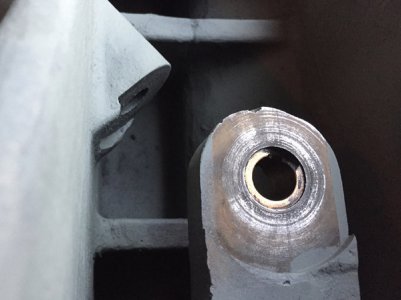

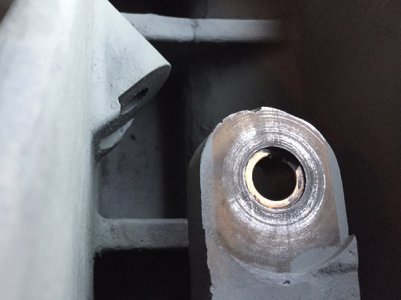

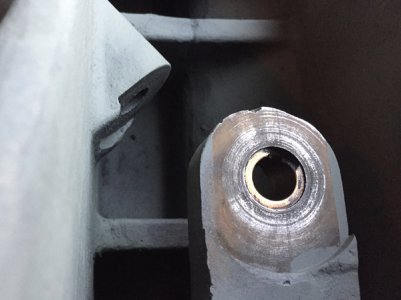

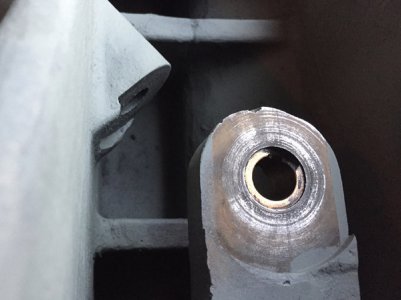

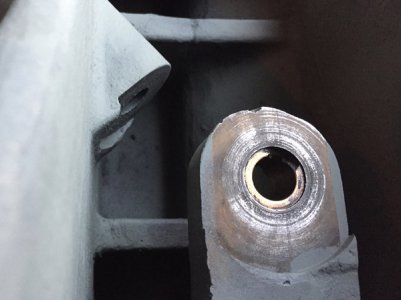

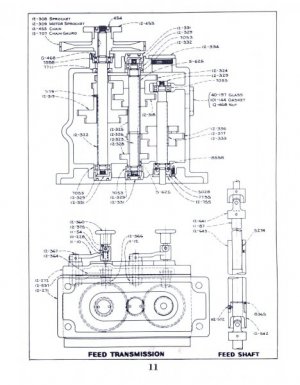

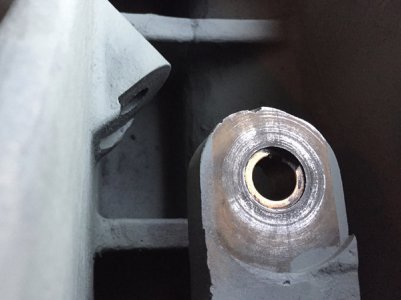

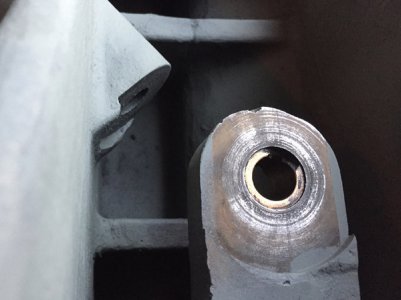

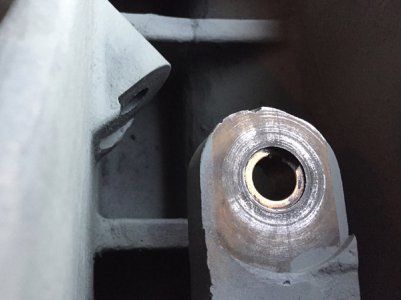

I picked up a VN12 a couple weeks ago. I tore it down for restoration. Everything is in really good shape except the feed screw that raises the knee is bent. The threaded portion of the screw doesn't seem to be bent. The bend seems to be in the last 2" where the shaft fits into the knee. The bend is about .050" so the high to the low measures .100".

Any ideas how I should straighten it without breaking it?

Thanks,

Greg

I picked up a VN12 a couple weeks ago. I tore it down for restoration. Everything is in really good shape except the feed screw that raises the knee is bent. The threaded portion of the screw doesn't seem to be bent. The bend seems to be in the last 2" where the shaft fits into the knee. The bend is about .050" so the high to the low measures .100".

Any ideas how I should straighten it without breaking it?

Thanks,

Greg