I've been absolutely swamped at home lately with various projects around the house and a couple of customer jobs so haven't really had time to look at the volvo in weeks.

Whenever I have some time over(breaks at work and such) I'm trying to do research related things so at least some progress is being made.

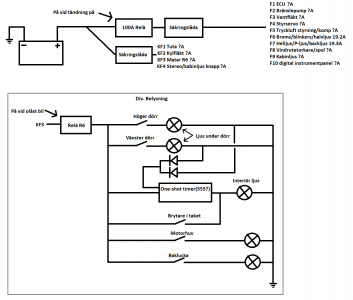

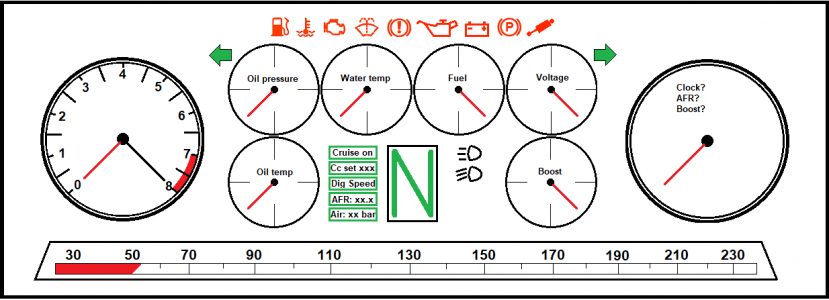

Currently working on a new electrical layout, fuel system, control system for the pneumatics and so on.

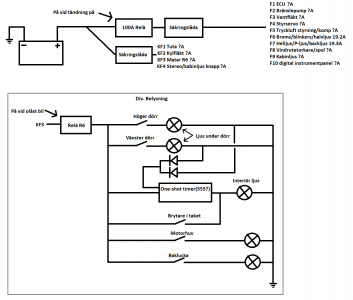

It's all in Swedish but it's just the basic stuff.

Battery will go into a 100A relay that activates when ignition is on, this feeds a fusebox(säkringslåda) that so far has 10 fuses.

This will feed ECU, fuelpump, ventilation fan, powersteering, aircompressor/control, all kinds of lights, window washers, dash etc.

A second fusebox is directly coupled to the battery and will only feed the horn, cooling fan, Relay R6, stereo and a button to light up the cabin.

Relay R6 will go active when the car is unlocked, this will allow all kinds of lights to be on.

A small module will control the cabin lights and will light up the cabin if either door is opened or the car has just been unlocked, for 30 seconds or so.

Then a bunch of switches for lights under each door, in the trunk and under the hood if any of them are opened.

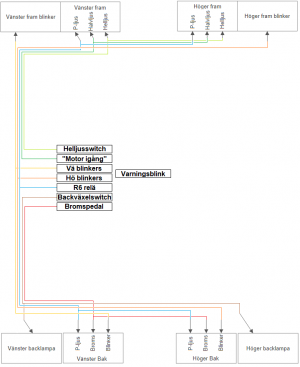

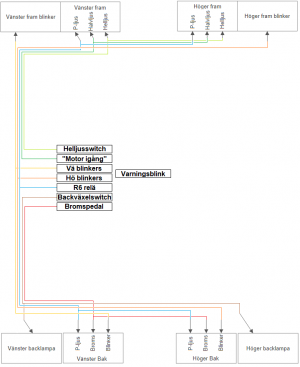

The right picture is mostly to aid myself when it's time to make the loom to keep track of turn signals, low/high beam, brakes etc.

Seperate from those schematics I'm also working on the pneumatic module.

This will get current from the relay controlled fusebox.

The idea at the moment is to a level sensor at each wheel and allowing this module to inflate/deflate the bags to maintain the car perfectly level at whatever ride height you select.

The bags got internal bumpstops so the idea is to have a 'Slam' mode which is basically parked car with empty bags.

'Low' would be low as possible but still driveable.

'Normal' would be a height that allows you to casually drive, speedbumps shouldn't be an issue etc

And finally 'High' setting if you're on a gravel road or what not. I don't imagine this getting used a lot but good to have.

Once a setting is applied, the module will check if the speed is below 10kph(or whatever seems to work IRL) and then start leveling the car to the new height.

I need to finish a deck build at home then re-organize my entire garage/workshop because it's a complete mess and I can't concentrate when I'm constantly looking for the tools I need etc.

After that I can hopefully get back on the Volvo.

Honestly feels like crap not having the time to work on it when it's so close to having wheels again, but that's just life.

Sometimes other things take priority.