- Joined

- Jan 2, 2014

- Messages

- 8,851

It's looking great!

Thanks for the update.

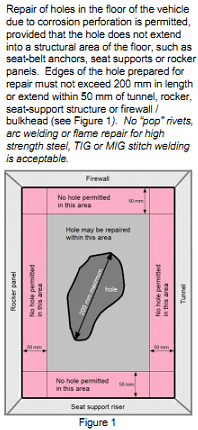

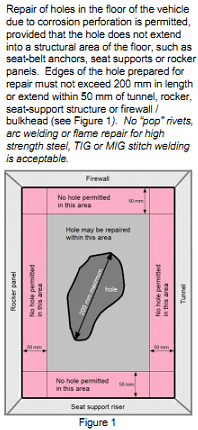

I actually thought about this thread last week when I stumbled across some of my local requirements for automotive floor-pan replacements:

I would argue that the requirements above are BS as I could use MIG or TIG, but not "arc welding"?!?!

Obviously written by someone that does not understand the technology behind the words they are using.

Note: NONE of this is meant as any type of put-down.

You are doing an amazing job that I would not be afraid to either drive myself or have on the road with me.

It was just the huge disconnect between what you are doing and these silly local rules that made me laugh out loud.

Brian

Thanks for the update.

I actually thought about this thread last week when I stumbled across some of my local requirements for automotive floor-pan replacements:

I would argue that the requirements above are BS as I could use MIG or TIG, but not "arc welding"?!?!

Obviously written by someone that does not understand the technology behind the words they are using.

Note: NONE of this is meant as any type of put-down.

You are doing an amazing job that I would not be afraid to either drive myself or have on the road with me.

It was just the huge disconnect between what you are doing and these silly local rules that made me laugh out loud.

Brian