- Joined

- Feb 28, 2019

- Messages

- 131

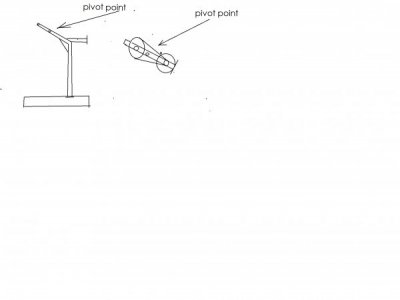

cannot find a 20 in pulley that fits my needs, so i will drop the motor pulley down to a 2in. Anyway, the Lathe Drive project is nearing completion, pictures of the shaft assembly. Building final frame and shimming the bearing caps remains.