- Joined

- Oct 8, 2014

- Messages

- 127

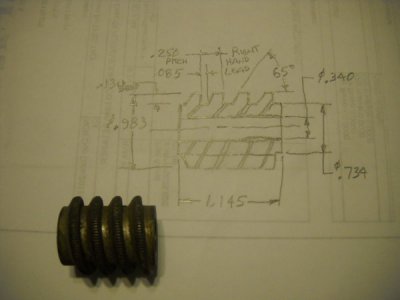

Got this guy many tears back & always wanted to fix it. Have the time now, but what would a guy use to make the threads? They aren't acme. Ideas appreciated.

Thanks,

Mark

Thanks,

Mark