- Joined

- Nov 27, 2018

- Messages

- 12

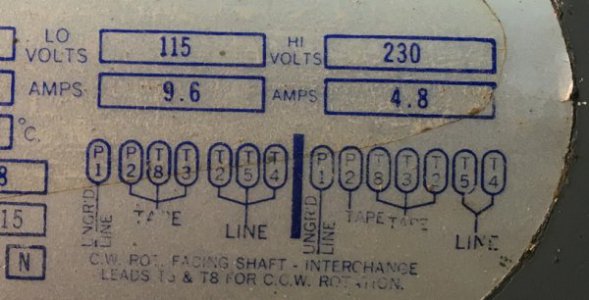

Bought a used drill press the other day, has a old GE singlephase ac 1/3 hp motor. I can grab the chuck with a gloved hand and stop the motor.

Is it just old, can it be improved (torque) or is 1/3 hp just that weak? I dont want to spend hundreds on a motor if I can swap out a part or something.

Sorry if this is a stupid or obvious question, but its all new to me. Thanks

Is it just old, can it be improved (torque) or is 1/3 hp just that weak? I dont want to spend hundreds on a motor if I can swap out a part or something.

Sorry if this is a stupid or obvious question, but its all new to me. Thanks