- Joined

- Dec 3, 2013

- Messages

- 1,844

I blame RayC for planting the seed in my head to build a positioner. See his post https://www.hobby-machinist.com/threads/welding-rotary-table.64640/

I have another project that has a lot of round bits to weld so it made sense to make one. This is my slightly more complicated re-mix of Rays concept.

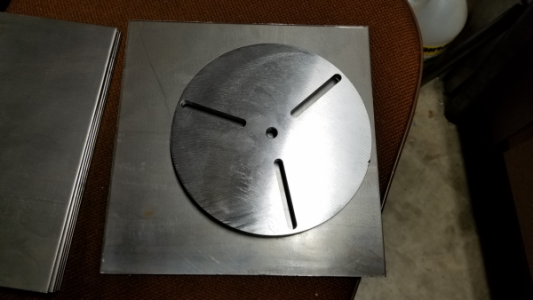

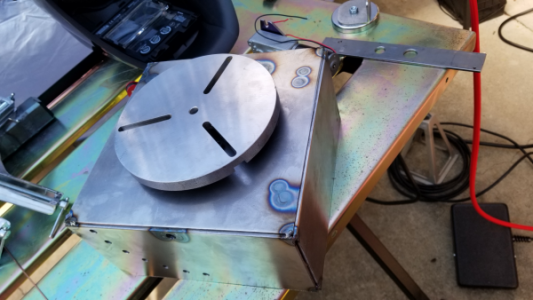

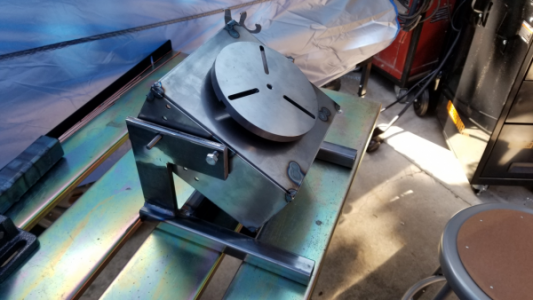

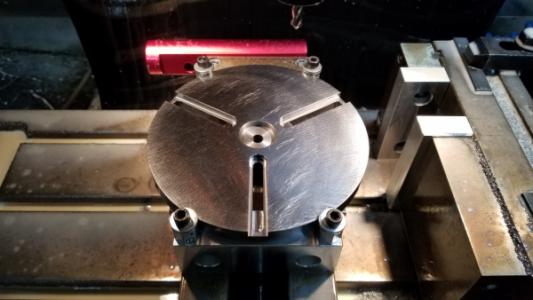

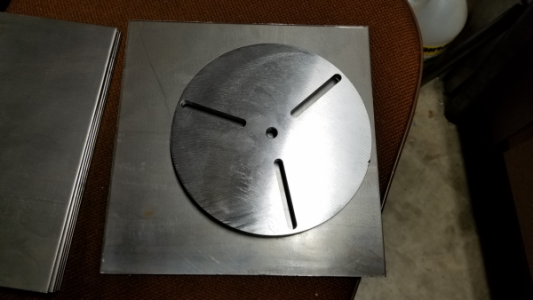

The table is 6" x .5" steel. Slots are sized for a 1/4" nut across the flats. No need to make special nuts. Slots were machined on the CNC mill. I had to get creative on holding a 6" disc in a 4" vise.

Main shaft, bearing block, taper roller bearing and retainer/ground commutator.

Main shaft is pressed into the table. No welds.

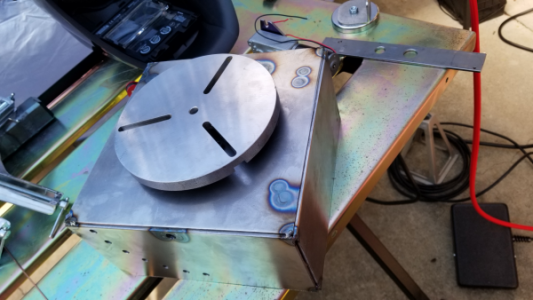

The base is made from 11 ga. steel sheet. I had my local supplier cut them to size for me. Cost me $13 out the door. 12v power supply and speed control are mounted to 1" x 1/8" flat and then to threaded stand-offs welded to the underside of the base top. There is a anti-rotation bracket attached to the motor gearbox with a slot that engages a 1/4" dowel pin which is pressed into the bearing block. A set screw secures the gearbox shaft to the main shaft. The motor/gearbox are only supported by the shaft.

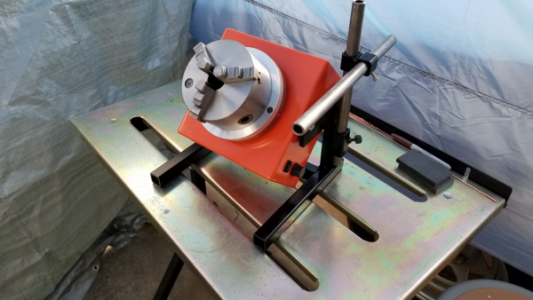

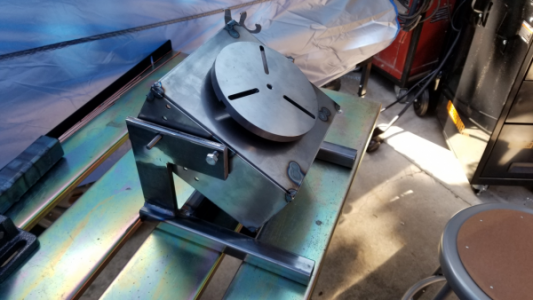

The stand is made from 1" square tube and 3/8" x 2" steel flat. The table can be set from 0 - 90 degrees in 15 degree increments.

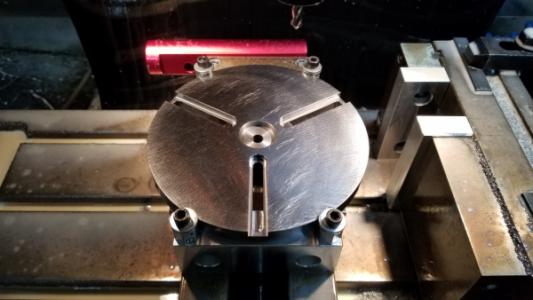

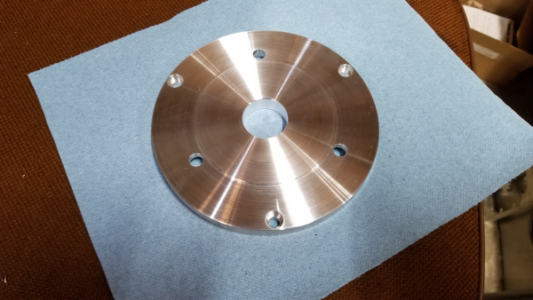

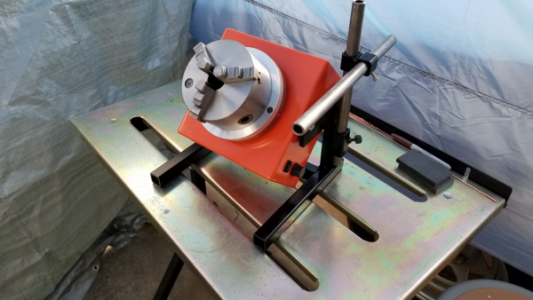

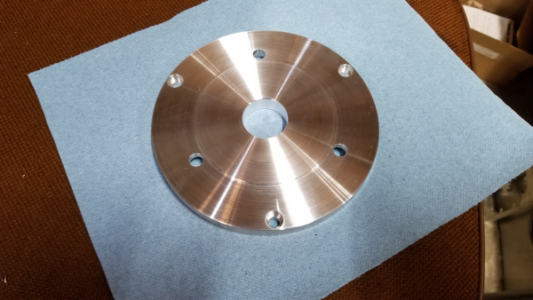

Adapter for a 5" 3-jaw chuck

Painted, wired up and ready to go. I did the table ground a little different than RayC. I used 3 strands of 1/4" copper ground strap which wraps around the shaft retainer and is tensioned with a spring. There is a ground lug for the welder ground clamp on the bottom strip that holds the power cable gland and the 2-pin foot switch connector. I also added an adjustable hand support system.

I have another project that has a lot of round bits to weld so it made sense to make one. This is my slightly more complicated re-mix of Rays concept.

The table is 6" x .5" steel. Slots are sized for a 1/4" nut across the flats. No need to make special nuts. Slots were machined on the CNC mill. I had to get creative on holding a 6" disc in a 4" vise.

Main shaft, bearing block, taper roller bearing and retainer/ground commutator.

Main shaft is pressed into the table. No welds.

The base is made from 11 ga. steel sheet. I had my local supplier cut them to size for me. Cost me $13 out the door. 12v power supply and speed control are mounted to 1" x 1/8" flat and then to threaded stand-offs welded to the underside of the base top. There is a anti-rotation bracket attached to the motor gearbox with a slot that engages a 1/4" dowel pin which is pressed into the bearing block. A set screw secures the gearbox shaft to the main shaft. The motor/gearbox are only supported by the shaft.

The stand is made from 1" square tube and 3/8" x 2" steel flat. The table can be set from 0 - 90 degrees in 15 degree increments.

Adapter for a 5" 3-jaw chuck

Painted, wired up and ready to go. I did the table ground a little different than RayC. I used 3 strands of 1/4" copper ground strap which wraps around the shaft retainer and is tensioned with a spring. There is a ground lug for the welder ground clamp on the bottom strip that holds the power cable gland and the 2-pin foot switch connector. I also added an adjustable hand support system.