- Joined

- Mar 26, 2018

- Messages

- 8,397

Hi,

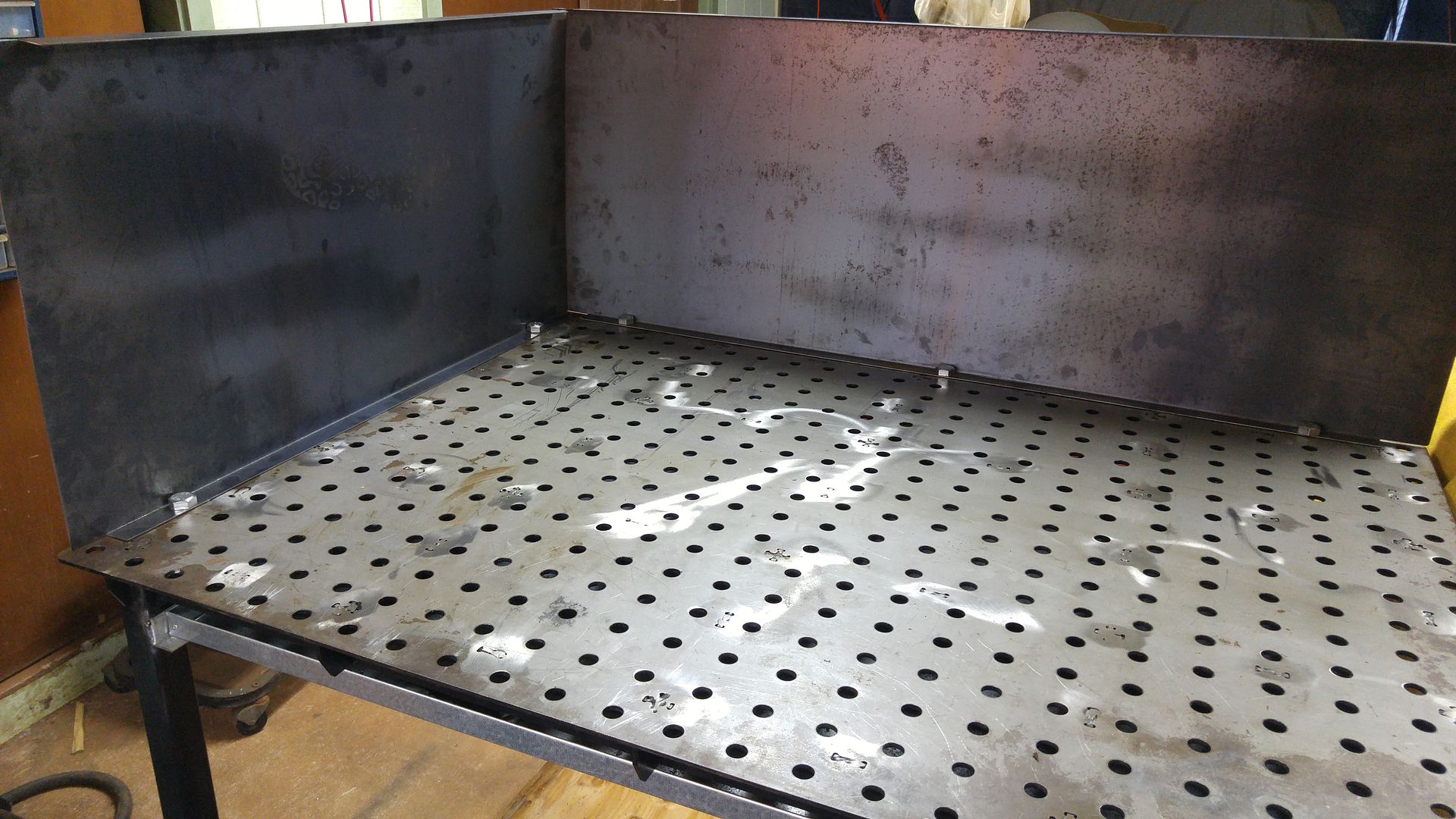

I have been planning to build a welding table. I want it to be portable but stable. I am thinking 2 wheels, just lift one end and the wheels kick in for easy movement. The dimensions= 30" X 36". I was hoping to add a copper plate for the top. Wow, I priced a 1/2" 30 X 30" plate it was $1,500. I down sized to 1/8 thickness and it was only $500.

At work we have 3 shop tables, they are all 72" by 24", each has a 1/2" copper top. We don't weld on them. I wonder if I ask my boss if he would mind if I cleaned up one of those tables and replaced the top with a more convenient metal top?

I am thinking thin wall 2x3" steel stock. Make the cuts on my band saw, dress the cuts and TIG weld the assembly.

Any plans on-line or do you know of a source for any ideas in this area? I would like to have a shelf for materials, something to hold all my welding accessories.

Thanks,

Jeff

I have been planning to build a welding table. I want it to be portable but stable. I am thinking 2 wheels, just lift one end and the wheels kick in for easy movement. The dimensions= 30" X 36". I was hoping to add a copper plate for the top. Wow, I priced a 1/2" 30 X 30" plate it was $1,500. I down sized to 1/8 thickness and it was only $500.

At work we have 3 shop tables, they are all 72" by 24", each has a 1/2" copper top. We don't weld on them. I wonder if I ask my boss if he would mind if I cleaned up one of those tables and replaced the top with a more convenient metal top?

I am thinking thin wall 2x3" steel stock. Make the cuts on my band saw, dress the cuts and TIG weld the assembly.

Any plans on-line or do you know of a source for any ideas in this area? I would like to have a shelf for materials, something to hold all my welding accessories.

Thanks,

Jeff