- Joined

- Mar 26, 2018

- Messages

- 8,397

Hello,

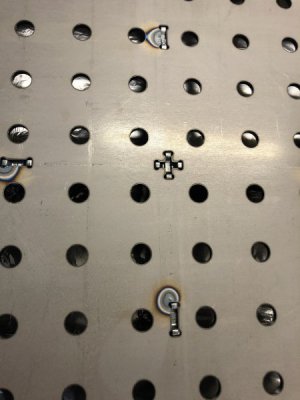

I finally got around to putting together my 24" X 36" Certiflat, welding table with the optional legs and locking castors.

Web site https://weldtables.com/

The fit and finish is very good IMHO. If you have not seen this product they put together a very versatile platform with lots of mounting options to hold your irregular work to be welded.

This is also a great time to use my TIG welder.

I'll post a few pics as I put this together over the next couple days. So far, I am very satisfied.

Is this the right place to post this??

![IMG_0600[1].JPG IMG_0600[1].JPG](https://www.hobby-machinist.com/data/attachments/226/226012-edba11e7eaf0092c8288c38d44552795.jpg)

![IMG_0601[1].JPG IMG_0601[1].JPG](https://www.hobby-machinist.com/data/attachments/226/226013-e9caaad0e57064719eb721fbcd93276f.jpg)

I finally got around to putting together my 24" X 36" Certiflat, welding table with the optional legs and locking castors.

Web site https://weldtables.com/

The fit and finish is very good IMHO. If you have not seen this product they put together a very versatile platform with lots of mounting options to hold your irregular work to be welded.

This is also a great time to use my TIG welder.

I'll post a few pics as I put this together over the next couple days. So far, I am very satisfied.

Is this the right place to post this??

![IMG_0600[1].JPG IMG_0600[1].JPG](https://www.hobby-machinist.com/data/attachments/226/226012-edba11e7eaf0092c8288c38d44552795.jpg)

![IMG_0601[1].JPG IMG_0601[1].JPG](https://www.hobby-machinist.com/data/attachments/226/226013-e9caaad0e57064719eb721fbcd93276f.jpg)