- Joined

- Jan 28, 2016

- Messages

- 253

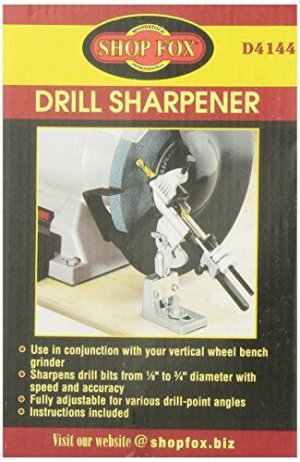

Side loading a grinding wheel? Bad stuff can happen when you do this. These types of wheels are not designed to be side loaded and here is a tool that is designed to do just that! I found this when I was looking for a cheaper alternative to a drill doctor 750X

I wonder if anyone had had a wheel shatter using this device? Looks like a lawsuit in the making to me.

I wonder if anyone had had a wheel shatter using this device? Looks like a lawsuit in the making to me.