S

Spike

Forum Guest

Register Today

While tinkering around with the Atlas QC-54 I recently acquired I noticed that the auto cross feed knob on mine does not spin when the feed screw is running like all the ones in the youtube videos I have been watching.

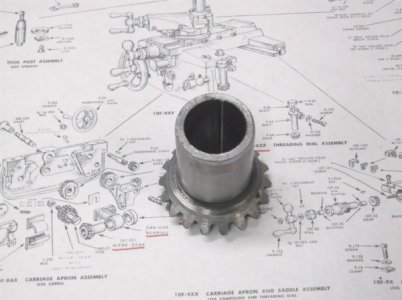

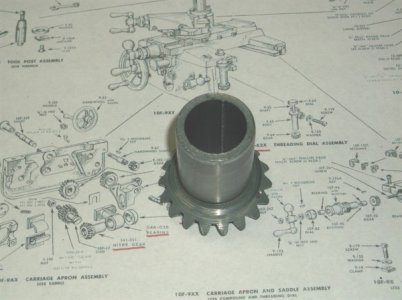

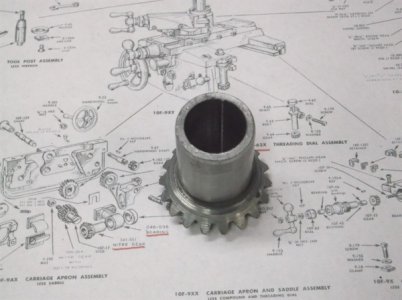

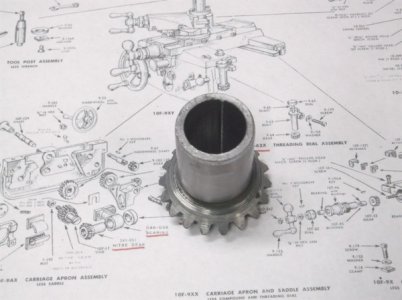

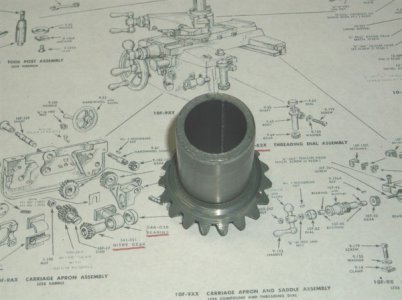

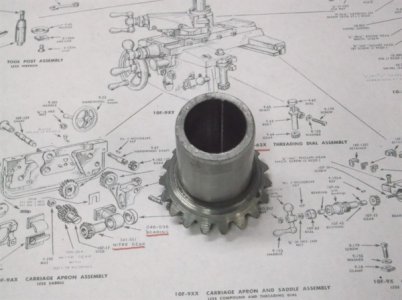

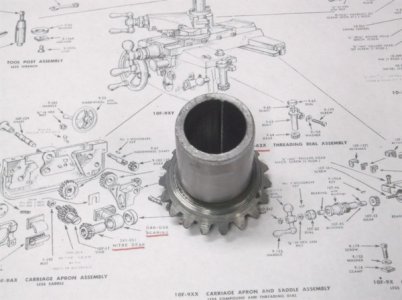

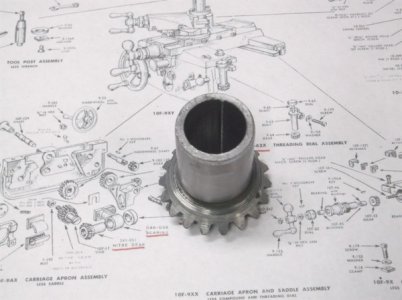

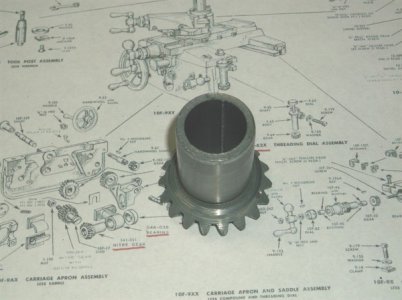

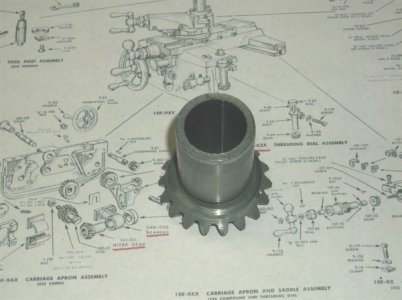

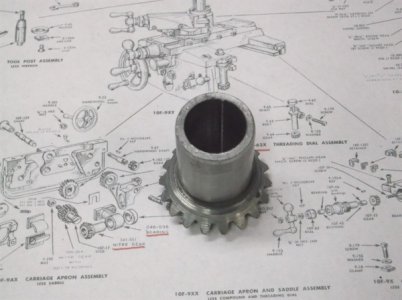

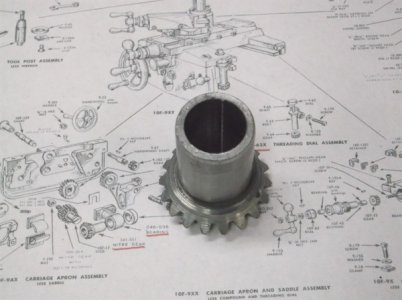

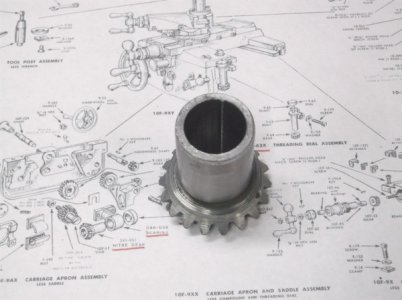

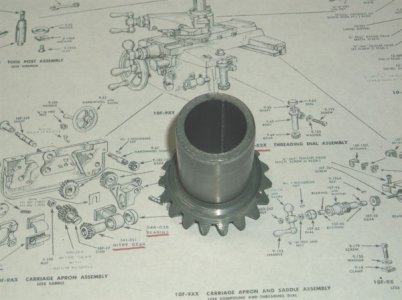

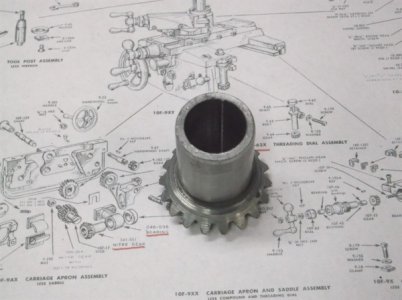

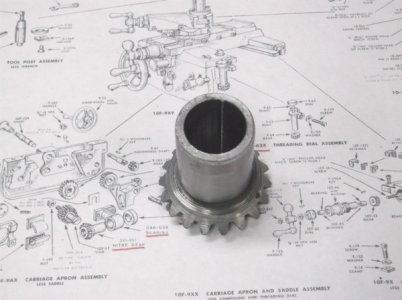

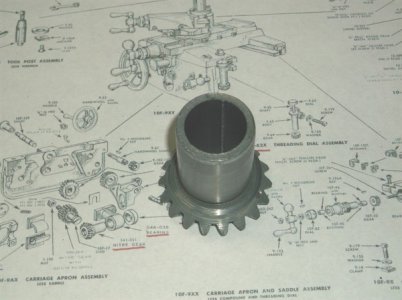

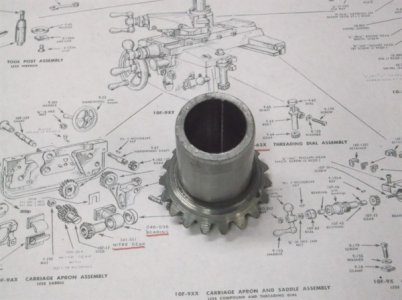

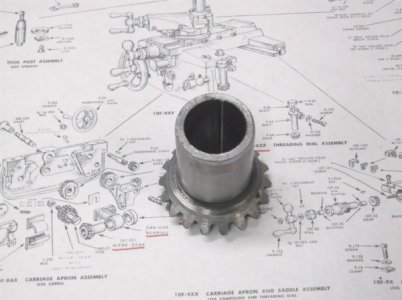

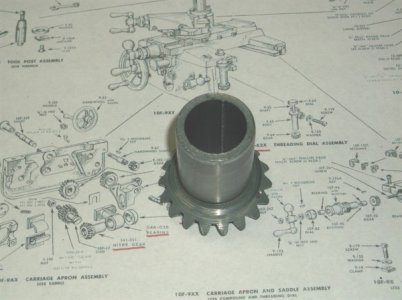

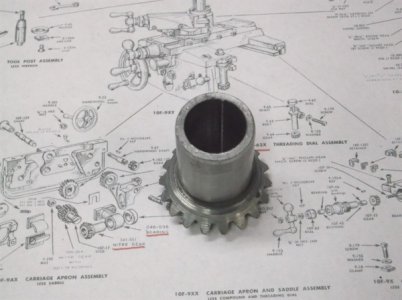

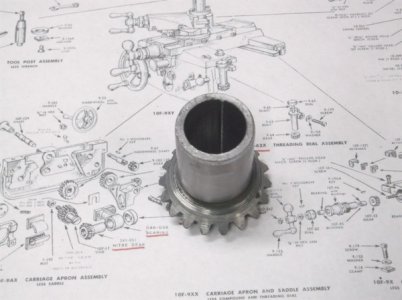

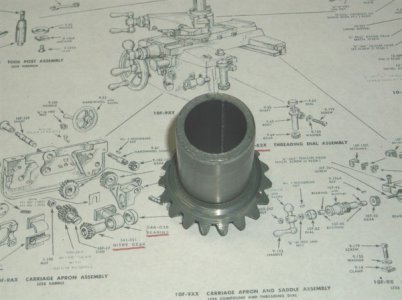

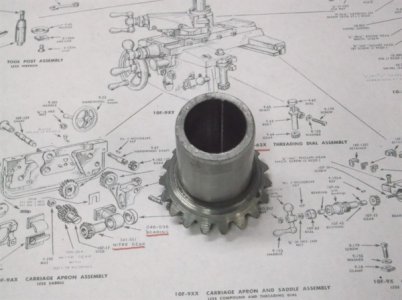

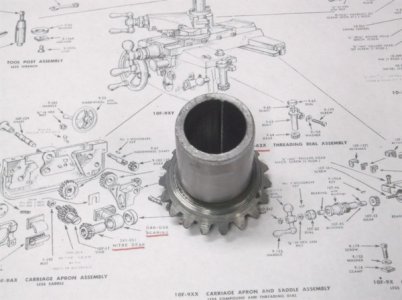

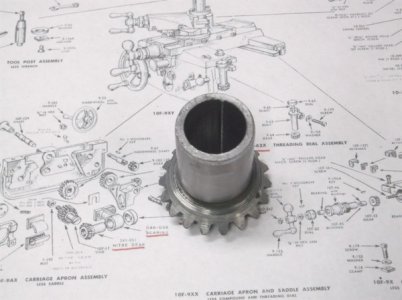

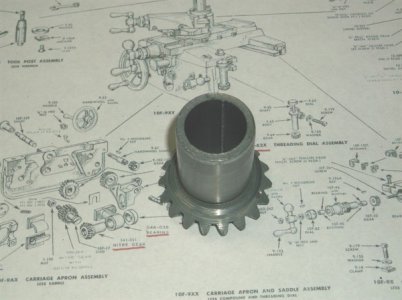

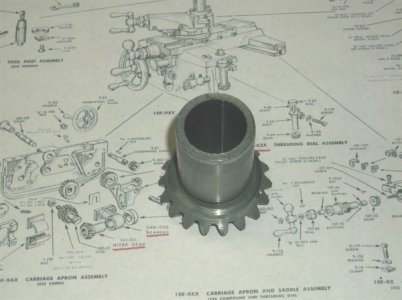

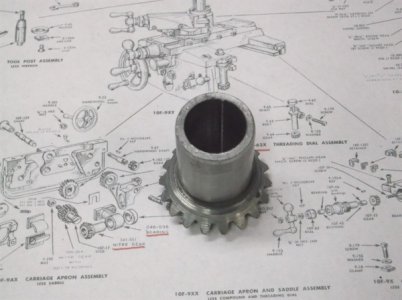

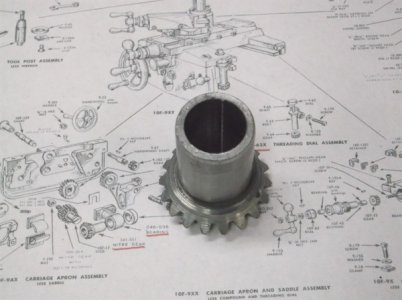

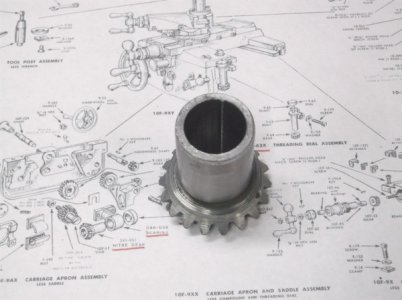

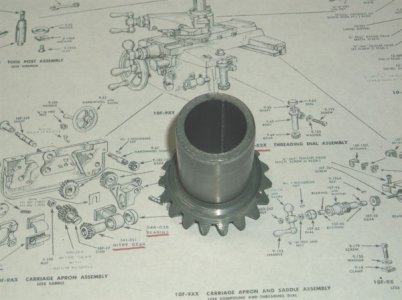

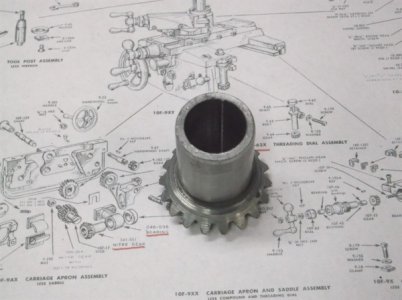

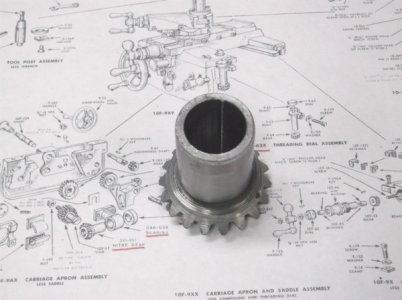

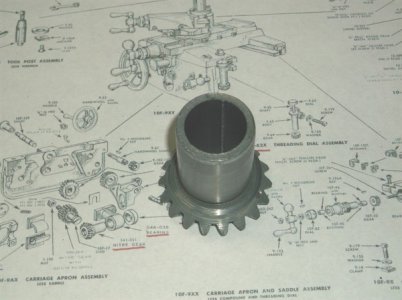

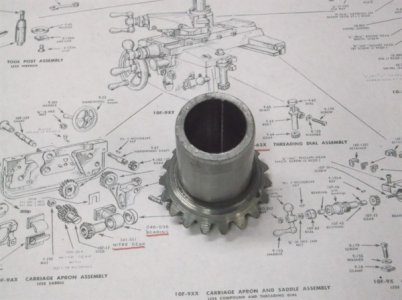

I have no idea if I will ever even need that feature but it bugged me enough to take the apron off and take a look. Here is what I found:

I know the pics are horrible but even so you can see that while I assume there is supposed to be a spline inside the sleeve there is none, only a bit of a ridge. To my untrained eye it still seems I found the problem though.

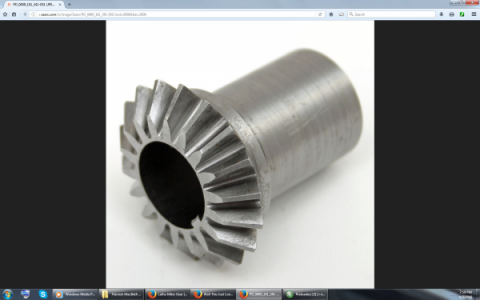

The exploded view I found says the bad part is the 341-051 Mitre Gear. Anyone know where I may get this part? Anyone know if I'll need a loan for it? Thanks in advance!

-Spike

I have no idea if I will ever even need that feature but it bugged me enough to take the apron off and take a look. Here is what I found:

I know the pics are horrible but even so you can see that while I assume there is supposed to be a spline inside the sleeve there is none, only a bit of a ridge. To my untrained eye it still seems I found the problem though.

The exploded view I found says the bad part is the 341-051 Mitre Gear. Anyone know where I may get this part? Anyone know if I'll need a loan for it? Thanks in advance!

-Spike