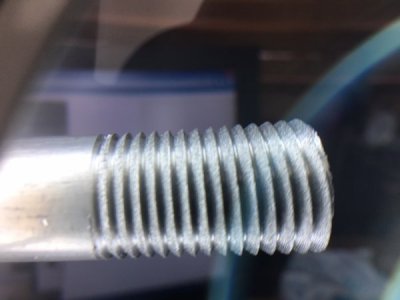

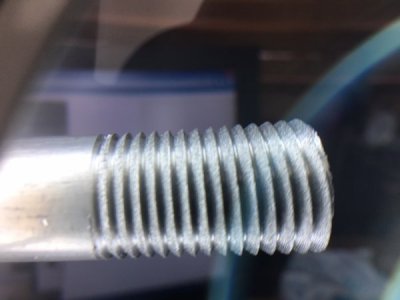

My threads are not vertical but seem to layover to one side. Using a sharpe 60 degree cutter, compound set at 29 1/2 degrees, cutter at 90 degrees to work.

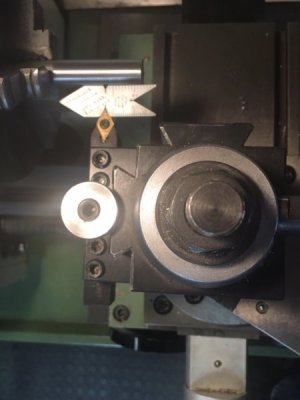

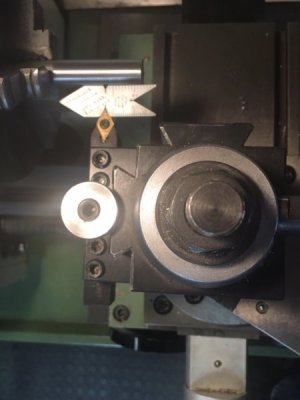

I have added some photos of my setup. The pictures of the thread were taken through a magnifying light. I am keeping the cross slide at zero and feeding with the compound.

I have added some photos of my setup. The pictures of the thread were taken through a magnifying light. I am keeping the cross slide at zero and feeding with the compound.

Last edited: